Contact

Address

DESCRIPTION

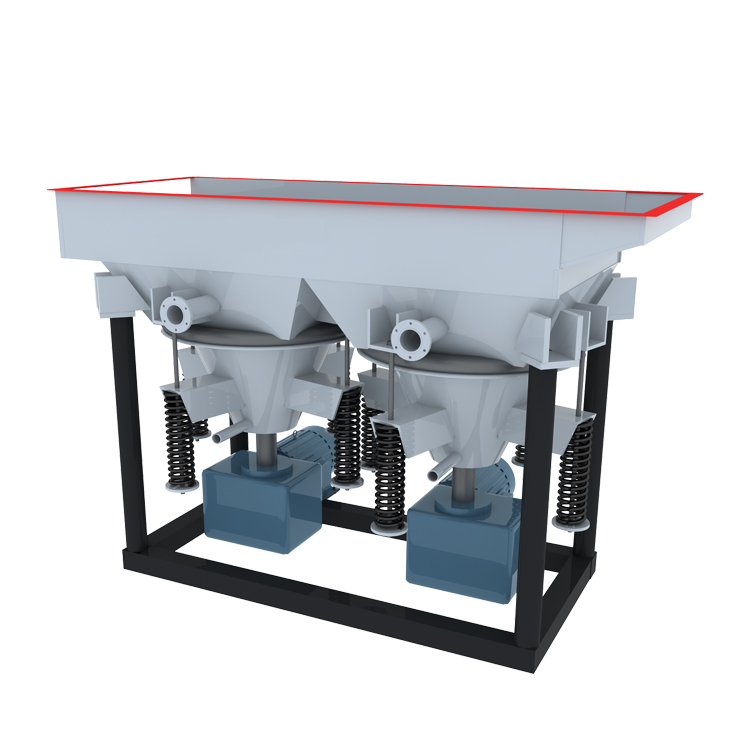

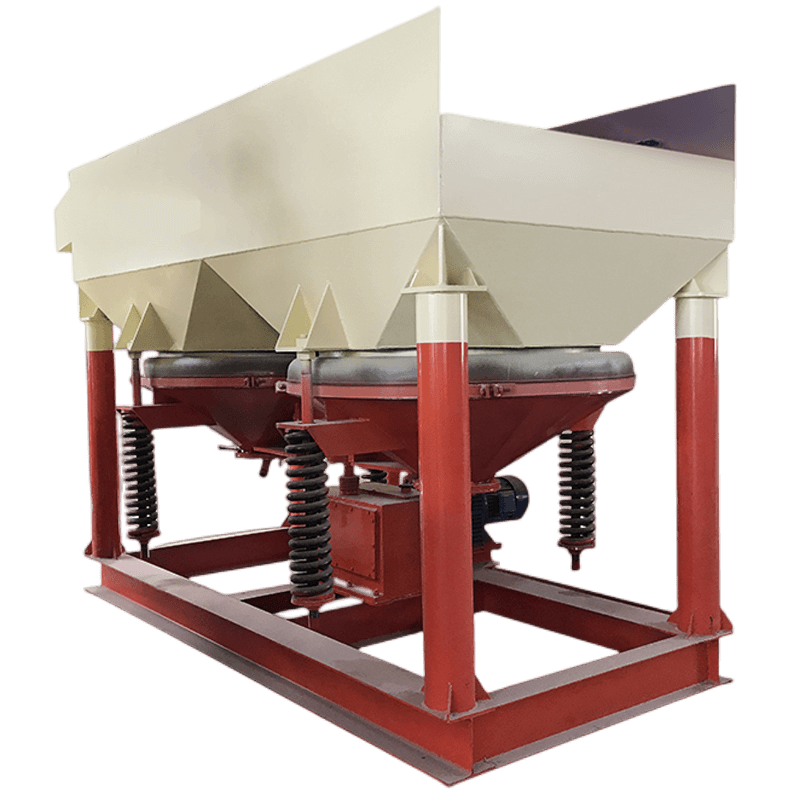

A Jigging Machine, also known as a jig or jig separator, is a mechanical device used for mineral separation and concentration. It is primarily employed to segregate mixed ores or minerals into different grades based on their density differences. Jigging machines find widespread applications in the mining and metallurgical industries, as they are instrumental in efficiently extracting valuable ores from raw materials while separating them from waste or lower-value minerals.

The basic operating principle of a jigging machine is as follows:

Material Loading: The mixed ores or minerals are loaded into the jigging machine’s feed trough or hopper, typically by means of vibration or gravity feed.

Up-and-Down Motion: Once the materials are loaded into the feed trough, the jigging machine undergoes a periodic up-and-down motion. This motion creates a water flow while generating centrifugal forces, leading to the stratification of materials into different layers.

Separation: Based on the density of the ores or minerals, heavier materials tend to settle at the bottom of the feed trough, while lighter materials rise to the top. This stratification process can be repeated multiple times for further separation.

Collection: Ultimately, the heavier, separated ores are typically collected and discharged from the bottom of the feed trough, while the lighter materials are discharged from the top, either for further processing or disposal.

Jigging machines come in various designs and types, including manually operated jigs and automated electric jigs. They can vary based on the materials being processed and the processing capacity required.

Major application areas include:

Metal Mining: Used for the separation of gold, copper, tin, lead, manganese, and other metallic ores.

Coal Mining: Employed for coal concentration and grading, reducing ash and sulfur content.

Gemstone and Gem Mining: Utilized for the extraction of gemstones like diamonds and sapphires.

Scrap Metal Recycling: Applied in the recovery of precious metals, such as gold, from e-waste.

Heavy Mineral Separation: Used in the separation of heavy minerals like tungsten, tin, and manganese ores.

Jigging machines are effective separation devices that improve ore quality and minimize waste. They play a critical role in the mining and metallurgical industries, assisting companies in enhancing production efficiency and resource recovery.

According to different usage scenarios on-site, our company has developed dozens of models and hundreds of specifications for hopper screens. In the selection process, guided by a sense of responsibility to our users, we comprehensively consider factors such as the processing capacity of coal preparation plants, coal quality characteristics, particle size composition, and product requirements. Our aim is to provide users with reliable, durable, high-quality, and efficient hopper screens.

Additionally, we can undertake the overall design of hopper coal preparation plants, equipment selection, and redesign of hopper coal preparation plants based on existing sites.