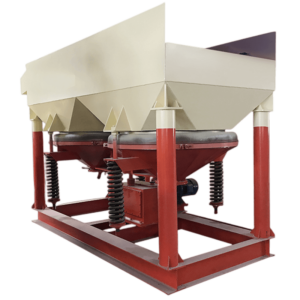

In the field of coal, mining and other resources development and processing, JDT series vibrating jigger has become the key equipment to realise the effective separation and purification of resources by virtue of its high efficient sorting capacity and reliable performance.

Choosing the right type of jigger can respond to production tasks with higher processing capacity, reduce equipment idling and waiting time, and significantly increase the output per unit time. In terms of cost control, the right type of jigger can reduce energy consumption and maintenance costs, and avoid the waste of resources caused by mismatched equipment.

In terms of product quality, accurate selection can ensure that the jigger can accurately sort the materials and obtain higher purity concentrate and lower impurity content tailings.

It can be seen that whether the selection of JDT series vibrating jigger is accurate or not is directly related to the economic benefits and market competitiveness of the enterprise, so how to choose the right model of JDT series vibrating jigger?

一.Analysis of the working principle of JDT series vibrating jigger

The working principle of JDT series vibrating jigger is based on the density difference.

Inside the jigger, the water flow produces periodic up and down pulsations. When the water rises, the material is held up by the water flow, the bed begins to loosen, the less dense material is more likely to be carried by the water flow upward movement; and the denser material, due to its own gravity is larger, in the rising water flow in the movement of the relatively slow. With the decline of the water flow, the density of the material quickly sink, through the loose bed, gradually moving to the bottom, while the density of the material is small to stay in the upper layer.

Through such constant pulsation, the materials are gradually stratified according to the difference in density, like an orderly ‘queue’. Impurities such as gangue with high density sink to the bottom layer, while fine coal with low density, etc. floats on the top layer. Eventually, through the specific discharging device, the materials of different layers are discharged separately, realising the efficient sorting of materials. This sorting principle based on density difference is the cornerstone of the JDT series vibrating jigger’s high efficiency, which ensures that it can operate stably under all kinds of complicated working conditions and accurately complete the task of material sorting.

二.JDT Series Vibrating Jigger Unique Advantages

From the structural point of view, its design is simple and clear, without too many complex parts, which not only makes the equipment less difficult to manufacture, the cost can be controlled, and more importantly, provides great convenience for the subsequent maintenance work.

At the same time, its operation and maintenance costs are also at a lower level, the energy consumption of the equipment is low, the daily maintenance requires little human and material resources, further reducing the operating costs of enterprises.

Wide range of particle size is another significant advantage of JDT series vibrating jigger, which is capable of handling materials with different particle sizes from 25mm to 400mm, whether it is large raw coal or smaller particles after preliminary crushing, all of them can be effectively sorted in this equipment. This wide applicability makes it play an important role in different mineral processing scenarios.

In terms of sorting precision, JDT series vibrating jigger is even better, its sorting efficiency can reach 95% – 98%, capable of separating fine coal from gangue and other impurities with high precision, providing a strong guarantee for enterprises to produce high quality products.

三.The selection of considerations

1.Material Characteristics

Particle size distribution is one of the important considerations. Although JDT series vibrating jigger has a wide range of processing particle sizes up to 25-400mm, the sorting behaviour of materials with different particle sizes in the jigger is very different.

For materials with larger particle size, such as raw coal lumps larger than 100mm, it is necessary for the jigger to provide more processing space and stronger pulsation force to ensure that they can be fully loosened and stratified. In this case, the jigger model with larger screen area and larger stroke should be selected, so as to ensure that the large granular materials have enough movement space to achieve effective sorting under the action of pulsating water flow. For materials with smaller particle size, such as coal particles less than 25mm, their movement in the jigger is more flexible, requiring finer control and smaller pulsation intensity, in order to avoid excessive disturbance leading to a decline in sorting accuracy. In this case, the jigger with relatively small stroke and number of strokes may be more suitable, which can realise the accurate sorting of small particles.

Density composition is also a key factor affecting the selection of jigger. When the density difference of different components in the material is large, such as the density difference between refined coal and gangue is obvious, the sorting effect of jigger is usually better, because under the action of pulsating water flow, materials with different densities can be more easily realised stratification. In this case, a jigger model with larger processing capacity can be selected to improve production efficiency.

Humidity also has a significant effect on the separation of materials in a jigger. Materials with high humidity have poor mobility and are easy to form agglomeration in the jigger, affecting the effect of stratification. Therefore, for materials with high humidity, it is necessary to choose a jigger with strong dewatering capacity, or increase the dewatering equipment before the jigger to reduce the humidity of the material, so as to ensure the normal operation of the jigger and the effect of sorting .

The hardness of materials should not be ignored. Harder materials, such as some metal ores, are more abrasive to the equipment in the process of jigging, which requires that the key parts of the jigger, such as sieve plate, discharge device, etc., have high wear resistance. When selecting the model, priority should be given to the jigger made of wear-resistant materials, or choose the jigger model with the design of easy-to-replace wear parts, in order to reduce the maintenance cost and downtime of the equipment .

2.Production demand

Production demand is the core orientation of enterprise operation, processing capacity is one of the most intuitive indicators, different scale enterprises have different requirements for the processing capacity of the jigger. The daily processing capacity of a small-scale mineral processing plant may only be a few hundred tonnes, while the daily processing capacity of a large-scale coal processing plant can reach thousands of tonnes or even tens of thousands of tonnes.

Take a medium-sized coal beneficiation plant with a daily processing capacity of 1,000 tonnes as an example, if its working time is 16 hours per day, then the hourly processing capacity requirement is about 62.5 tonnes. In this case, it is necessary to choose the jigger model with matching processing capacity, such as JDT1.2/2.4 model, whose processing capacity is 75-100t/h, which can meet the production demand of this coal processing plant.

3.Processing capacity

There are significant differences in the processing capacity of different models of JDT series vibrating jigger. Take JDT1.0/2.2.0 model as an example, its processing capacity is 50-75t/h, which is suitable for production scenarios with relatively small processing capacity, such as some small-scale beneficiation factories or enterprises that do not have high requirements on material processing capacity. The JDT2.4/4.8 model has a capacity of 350 – 400t/h, which is more suitable for large-scale coal beneficiation plants or industrial production with high demand for processing capacity.

In the actual selection, enterprises need to accurately choose the right model according to their own production scale and expected output.

4.Sorting precision

Different models of jigger have certain differences in sorting precision, which directly affects the quality of concentrates and tailings, enterprises need to weigh according to their own requirements for product quality when selecting the model.

The sorting efficiency of JDT series vibrating jigger can reach 95% – 98%, but the actual sorting precision of different models will be different when facing complex materials and different production requirements. Some models can easily achieve high-precision sorting when dealing with materials with large density differences, effectively separating fine coal from gangue and other impurities, and controlling the ash and sulphur indexes of fine coal at a low level.

However, when the difference in density of materials is small, or the quality of concentrate and tailings is very high, it is necessary to choose jigger models with higher sorting precision. These models are usually equipped with advanced automated control systems, which can precisely adjust the operating parameters of the jigger, such as pulsation frequency, amplitude, bed thickness, etc., according to the real-time situation of the materials, so as to realise the fine sorting of the materials, ensure that the quality of concentrates meets the high standard requirements, and at the same time, reduce the content of useful components in the tailings.

From in-depth analysis of material characteristics, clear production requirements, to a comprehensive consideration of site conditions, and then accurately control the processing capacity, particle size to adapt to the range, sorting accuracy, and other core points, each link is closely interlinked and indispensable.

In the actual selection process, it is important to avoid the blind pursuit of high performance and fall into the trap of low prices, while paying great attention to after-sales service. Only in this way can we ensure that the jigger will remain stable and efficient in long-term operation and create maximum value for the enterprise.

For enterprises that are facing the selection of JDT series vibrating jigger, I hope this article can be a powerful guide for you. In the selection process, we should fully combine our actual situation, use scientific methods and rigorous attitude to make wise decisions.