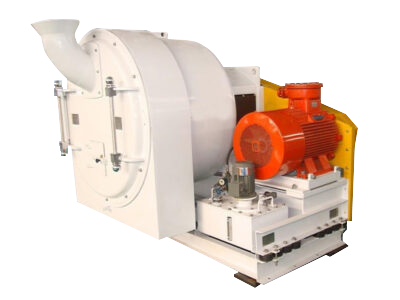

In the vast field of industrial production, horizontal dewatering centrifuge as an efficient solid-liquid separation equipment, plays an indispensable role. It is widely used in chemical industry, environmental protection, food, pharmaceuticals and other fields, and has become the core equipment to achieve efficient solid-liquid separation in the production process of many industries, and has made an important contribution to the improvement of production efficiency, product quality and environmental protection in various industries.

The working principle of horizontal dewatering centrifuge is based on the powerful effect of centrifugal force. When the equipment is started, the drum begins to rotate at high speed, generating a strong centrifugal force field. In this centrifugal force field, the material to be treated is introduced into the drum. Due to the difference in density between the solid particles and the liquid in the material, under the action of the centrifugal force, the solid particles with higher density will quickly settle towards the inner wall of the drum, while the liquid with lower density will be thrown towards the centre area of the drum. In this way, the solid and liquid can be quickly separated, and the purpose of solid-liquid separation is achieved. At the same time, the centrifuge is equipped with a screw conveyor that will continuously push the solid particles settled in the inner wall of the drum to one end of the drum, discharged from the slag discharge port, while the liquid flows out of the overflow port at the other end of the drum, thus completing the entire solid-liquid separation process.

一.Food Industry

1.Separation of starch and protein

In the starch industry, take sweet potato starch production as an example, during the processing from sweet potato to starch, starch needs to be separated from protein and other impurities. Horizontal dewatering centrifuges generate strong centrifugal force through high-speed rotation, which can accurately separate starch from protein, greatly improving the purity of starch. The starch separated by the centrifuge has high purity and few impurities, and is widely used in the production of vermicelli, pastries and other food products. In the modern wheat starch production process, the application of advanced equipment such as three-phase decanter centrifuge and double cone decanter centrifuge has realised the high-efficiency separation of starch and protein, which provides high-quality starch raw materials for the food industry.

2.Separation of oil and grease from impurities

In the field of oil and grease industry, whether it is the production of olive oil, peanut oil and other common edible oils, or the processing of industrial fats and oils, centrifuges play an indispensable role. Taking olive oil production as an example, the virgin oil pressed from fresh olive fruits often contains olive pomace and other impurities. Horizontal dewatering centrifuges use centrifugal force to quickly separate the oil from these impurities, which effectively ensures the purity and quality of olive oil and enables it to better retain its natural nutrients.

3.Beverage clarification

In the fruit juice and beverage industry, the application of horizontal dewatering centrifuges has brought revolutionary changes to the clarification of products. Take the production of apple juice as an example, the freshly squeezed apple juice contains a large amount of pulp residue, pectin and other suspended substances, which not only affect the appearance of the juice, but also may lead to precipitation in the storage process. Horizontal dewatering centrifuge through high-speed rotation, can quickly separate these suspended matter out, so that the apple juice becomes clear and bright. The juice treated by the centrifuge has a bright colour and fresh taste, which greatly improves the selling appearance and taste of the product and enhances market competitiveness.

二.Environmental protection field

1.Sewage treatment

In the city sewage treatment plant, a large amount of sludge produced in the process of sewage treatment, the water content is extremely high, if not effectively treated, not only will occupy a large amount of land resources, but also may cause secondary pollution to the environment. Horizontal dewatering centrifuge can quickly separate out the water in sludge through powerful centrifugal force, and greatly reduce the water content of sludge. Generally speaking, the water content of sludge treated by horizontal dewatering centrifuge can be reduced from 99% to 75% – 85%, and the volume of sludge is greatly reduced, which provides great convenience for the subsequent disposal of sludge to landfill, incineration and other work.

2.Industrial wastewater treatment

For chemical, printing and dyeing, papermaking and other industrial enterprises, a large amount of industrial wastewater generated during the production process, if discharged directly without effective treatment, will cause serious damage to the soil, water and other ecological environment. Chemical wastewater treatment, for example, chemical wastewater often contains a large number of heavy metal ions, organics and other harmful substances, horizontal dewatering centrifuge can quickly separate these solid impurities and harmful substances from the wastewater, so that the wastewater meets the discharge standards, and to achieve the recycling of water resources.

三.Chemical Industry

1.Separation of chemical raw materials

In chemical production, many raw materials exist in the form of mixtures, which need to be separated into pure components through efficient separation technology in order to meet the requirements of subsequent production processes. Take the production of plastic granules as an example, in the process of recycling waste plastics, the recycled plastic raw materials often contain impurities, water and different types of plastics mixed together. Horizontal dewatering centrifuges can quickly separate these impurities from plastic pellets through the powerful centrifugal force generated by high-speed rotation, improving the purity and quality of plastic pellets.

2.Chemical product purification

For some chemical products with extremely high purity requirements, such as pharmaceutical grade chemicals, electronic grade chemicals, etc., take the production of pharmaceutical grade chemicals as an example, in the process of drug synthesis, the reaction product often contains unreacted raw materials, by-products and other impurities, which, if not completely removed, will seriously affect the safety and efficacy of the drug. Horizontal dewatering centrifuge using its high-precision separation ability, can be separated from these impurities in the drug, so that the drug to achieve pharmaceutical purity standards.

五.Mining field

1.Mineral Dewatering

In the mining process, minerals extracted from the ground often contain a lot of water, which not only increases the transport cost, but also affects the subsequent processing. Take coal mining as an example, just mined raw coal with high moisture content, after the treatment of horizontal dewatering centrifuge, the moisture content can be greatly reduced, easy to transport and storage of coal. In metal mining, such as copper ore, iron ore, etc., horizontal dewatering centrifuges can also effectively remove the water in the minerals, and provide high-quality raw materials for the subsequent beneficiation, smelting and other processes.

2.Tailings Recovery

Tailings are the waste produced in the process of mining and beneficiation, but they often also contain a certain amount of useful components. If it is directly discharged, it will not only cause a waste of resources, but also cause serious pollution to the environment. Horizontal dewatering centrifuge is able to separate the useful components in the tailings from the waste residue through the high-speed rotation of the centrifuge, so as to achieve the secondary use of resources.

- 六. Pharmaceutical industry

In the process of drug research and development and production, it is often necessary to separate specific drug components, such as proteins, DNA, etc., from complex mixtures, which play a crucial role in the development of new drugs and the treatment of various diseases. Horizontal dewatering centrifuges use their powerful centrifugal force to quickly and accurately separate these drug components from mixtures, greatly improving the purity and efficacy of drugs. In the field of biopharmaceuticals, clean centrifuges have brought breakthroughs in biopharmaceutical research and development by virtue of their excellent separation capability. Through efficient separation and concentration of biological samples, the efficiency of biopharmaceutical research and development has been improved, and the purity and safety of drugs have been ensured.

七.Paper industry

In the paper industry, horizontal dewatering centrifuges are mainly used for pulp dewatering. Pulp is an important raw material for papermaking, and its moisture content directly affects the quality and production efficiency of paper. Horizontal dewatering centrifuge through high-speed rotation, can quickly separate the water in the pulp, improve the consistency of the pulp, and provide high-quality raw materials for the subsequent papermaking process. After the centrifuge dewatering pulp, it is easier to form in the papermaking process, and the strength and quality of the paper can be effectively improved.

八.Textile printing and dyeing industry

In the textile printing and dyeing industry, horizontal dewatering centrifuges are mainly used for wastewater treatment. The textile printing and dyeing process will produce a large amount of wastewater containing dyes, auxiliaries, suspended solids and other pollutants, which will cause serious pollution to the environment if discharged directly without effective treatment. Horizontal dewatering centrifuge can effectively treat these wastewater, through the centrifugal force of the wastewater in the solid impurities and pollutants separated out, so that the wastewater to meet the discharge standards, to achieve the recycling of water resources.

Horizontal dewatering centrifuge as an efficient solid-liquid separation equipment, with its unique working principle and excellent performance advantages, in the food, environmental protection, chemical industry, mining and many other industries play an irreplaceable key role. It not only provides efficient and accurate solid-liquid separation solutions for the production process of various industries, guarantees product quality and production efficiency, but also makes important contributions in resource recycling and environmental protection, and becomes an important force to promote the sustainable development of various industries.