Linear vibrating screen is a commonly used screening equipment, widely used in mining, building materials, chemical industry and other industries. It separates coarse and fine particles by vibrating the material on the screen surface. This article will introduce the working principle of linear vibrating screen to better understand its operation process.

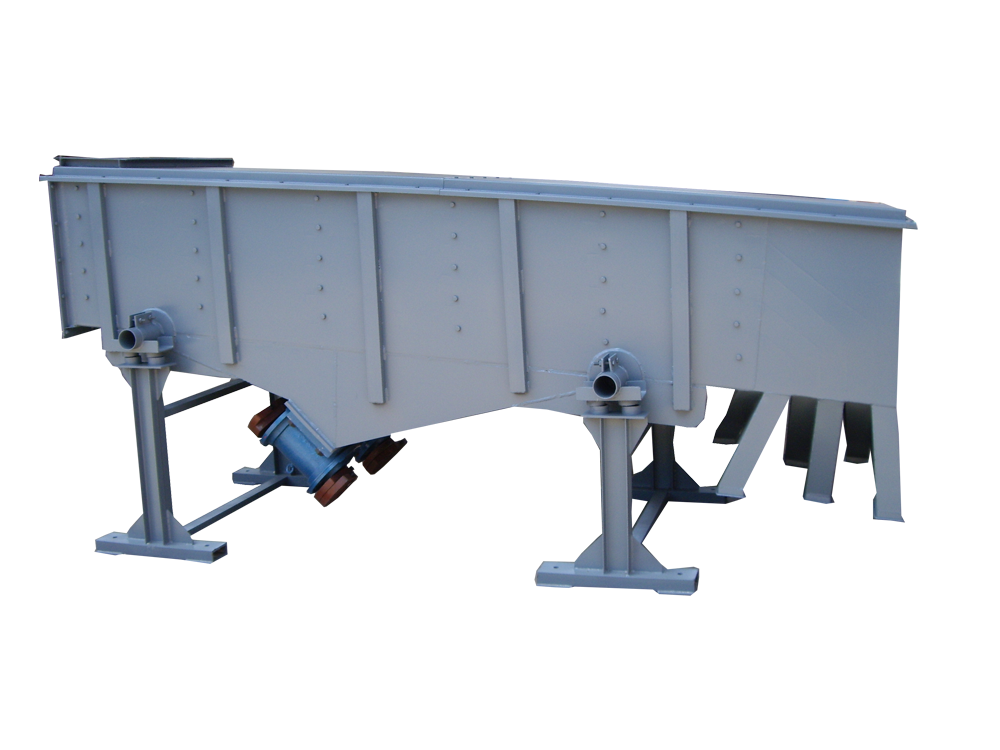

linear vibrating screen structure composition

Vibrating screen is generally composed of vibrator, screen box, support or suspension device, transmission device and other parts.

1.Vibrating screen vibrator: single-axis vibrating screen and double-axis vibrating screen vibrator, according to the eccentric weight configuration mode distinction, there are generally two types. Eccentric weight configuration to block eccentric type is better.

2.Vibrating screen screen box: screen box consists of screen frame, screen surface and its compression device. The screen frame is composed of side plates and beams. The screen frame must be rigid enough. It is mainly used to keep the screen flat and achieve normal screening. The screen box is the main component of the vibrating screen.

3.Vibrating screen supporting device: the supporting device of vibrating screen has two kinds of hanging type and seat type. Seat type installation is relatively simple, and the installation height is low. Generally, the seat type should be preferred. The supporting device of vibrating screen is mainly composed of elastic elements, and the commonly used ones are coil spring, plate spring and rubber spring.

4.Linear screen vibration damping spring: prevent the vibration from being transmitted to the ground, while supporting the full weight of the screen box, when installed, the spring is perpendicular to the ground.

5.Vibrating screen transmission device: vibrating screen usually adopts triangle belt transmission device. The structure of vibrating screen is simple. The number of revolutions of the vibrator can be selected arbitrarily. However, the belt is easy to slip when running. It may lead to clogging of the screen holes. The vibrating screen also has a direct drive using a coupling. The coupling can maintain a stable number of vibrator revolutions. And the service life is long. But it is difficult to adjust the rotation of the vibrator.

First, the working principle of linear vibrating screen

The vibration force generated by the vibration motor

Linear vibrating screen is usually equipped with one or more vibration motors, these vibration motors through the rotor internal eccentric device, so that the rotor produces high-speed rotation. Because the rotor’s center of rotation and the center of gravity do not coincide, so an eccentric force is generated, and this eccentric force is the vibration force generated by the vibration motor.

Vibrating force is transmitted to the screen surface

The vibration force generated by the vibration motor is transmitted to the screen box through the vibration spring on the vibration motor base or the vibrating screen frame. As the main part of the whole screening system, the screen box is equipped with screen mesh. When the vibration force is transmitted to the screen box, the screen box and screen mesh will also produce corresponding vibration.

The movement of materials on the screen surface

When the vibration force is transmitted to the screen box and screen, the screen box and screen will produce linear vibration. After the material is put on the screen surface, it produces jumping movement with the vibration of the screen surface, thus realizing the purpose of screening. Larger particles gradually move downward along the direction of vibration and pass through the screen, while finer particles are separated through the pores of the screen.

Screening efficiency influencing factors

The screening efficiency of linear vibrating screen is affected by a variety of factors, including the particle size of the material, humidity, viscosity, screen mesh aperture size, screen area and so on. Larger amplitude and vibration frequency can improve the screening efficiency, but too large amplitude will cause the material jump too high and affect the screening effect, so it needs to be reasonably adjusted according to the specific circumstances.

In general, the working principle of linear vibrating screen is to make the screen box and screen vibrate through the vibration force generated by the vibrating motor, and the materials will be screened and separated. This vibration screening method can separate granular materials in accordance with the particle size, widely used in various fields of screening work.

The characteristics of linear vibrating screen

1.Adopting block eccentric as the excitation force, strong excitation force;

2.Screen beam and screen box adopts high strength bolts, simple structure, convenient and quick maintenance;

3.Using tire coupling, flexible connection, stable operation;

4.Adopting small amplitude, high frequency and large inclination angle structure, which makes the machine with high screening efficiency, long life, low power consumption and low noise;

5.The design of the screen part of the design, can quickly change the screen, rapid tensioning, in addition to this design allows the use of a variety of screen mesh, such as nylon, special dragon, PP mesh, etc.;

6.Materials in the screen surface of the long stroke, high screening precision, large capacity;

7.In the sorting at the same time, the material long-distance transportation;

8.According to the particle size of the material, the probability of penetrating the screen, the production rate to change the screen spacing and angle of inclination;

9.According to the production site design of different shapes and structures.

一 . How to choose the right horizontal linear vibrating screen

1.Consider the characteristics of screening materials

Selecting a suitable horizontal linear vibrating screen needs to consider the characteristics of the screening material. Different materials have different requirements for screening equipment, such as particle size, shape, density, viscosity and so on. For different materials, it is necessary to choose different models, different specifications, different screen aperture of the horizontal linear vibrating screen.

2.According to the screening precision and handling capacity

Selecting a suitable horizontal linear vibrating screen also needs to consider the screening precision and processing capacity. In the case of high screening precision requirements, it is necessary to choose the horizontal linear vibrating screen with smaller mesh aperture, adjustable vibration frequency and amplitude to ensure the screening effect. In the case of high processing capacity requirements, it is necessary to choose vibrating screen equipment with large processing capacity, high screening efficiency and low maintenance cost.

3.The quality and performance of the equipment

The selection of horizontal linear vibrating screen also needs to consider the quality and performance of the equipment. For the same model of horizontal linear vibrating screen, there are differences in quality and performance between different manufacturers and different brands. You need to choose a horizontal linear vibrating screen with reliable quality, stable performance and low maintenance cost to avoid unnecessary impact on production.

二.How to choose the horizontal linear vibrating screen screening size

1、Choose suitable screen mesh

It is necessary to choose a suitable screen mesh according to the characteristics of the screening material. For the screening of different materials, it is necessary to choose different screen mesh, which can generally be determined according to the particle size, shape, density and other factors of the screening material. If not properly selected, it may affect the screening effect, or even damage the screen.

2、 determine the appropriate screening size

Secondly, according to the production process and requirements to determine the appropriate screening size. Different production processes and product requirements for screening size has different requirements. For example, for the production of coarse products, the need for a larger screen size, while for the production of fine products, the need for a smaller screen size. In addition, in the selection of screening size, but also need to consider the production capacity and screening efficiency, in order to ensure the production efficiency.

3、determine the screening capacity

It is necessary to determine the model and parameters of the horizontal linear vibrating screen according to the production capacity. Different models and parameters correspond to different screening capacity and production efficiency. Generally speaking, it is necessary to consider the particle size of the screened material, screening efficiency, processing capacity and other factors to choose the appropriate model and parameters. At the same time, when choosing horizontal linear vibrating screen, you also need to consider its reliability and maintenance cost to avoid unnecessary impact on production.

一.The working principle of linear vibrating screen

Its working principle of two vibrating machine shaft relative to the screen surface has a tilt angle, under the combined force of the excitation force and the self gravity of the material, the material is thrown up on the screen surface jumping forward for linear motion, so as to achieve the purpose of screening and grading of materials. Linear screen adopts double vibration motor drive, when the two vibration motors do synchronization, reverse rotation, the excitation force produced by its eccentric block in the direction parallel to the motor axis cancel each other, in the direction perpendicular to the motor axis superimposed as a joint force, so the trajectory of the sieve machine is a straight line.

Screening process: a large number of different particle size, coarse and fine mix of broken bulk materials into the screen surface, only part of the particles and the screen surface contact, due to the vibration of the sieve box, the screen material layer is loosened, so that the large particles would have existed in the gap is further enlarged, the small particles to take advantage of the opportunity to go through the gap, transferred to the lower level or on the transportation machine. As the small particles gap is small, large particles and can not pass through, so the original haphazard arrangement of the particles occurred in the separation of the group, that is, according to the size of the particles for the stratification, the formation of small particles in the lower, coarse particles on the rules of the arrangement.