Jigger is the main and core equipment of coal beneficiation plant, and its good or bad work plays a pivotal role in the technological level and economic benefits of coal beneficiation plant. Because, in the flotation coal processing plant, the output of jigging output of coal to account for about 80% of the total amount of coal, in the absence of flotation coal processing plant, the amount of coal is 100% of the coal plant. Therefore, it is very important to improve the operation technology of jigger to get good coal beneficiation effect.

Basics of operating a jigger

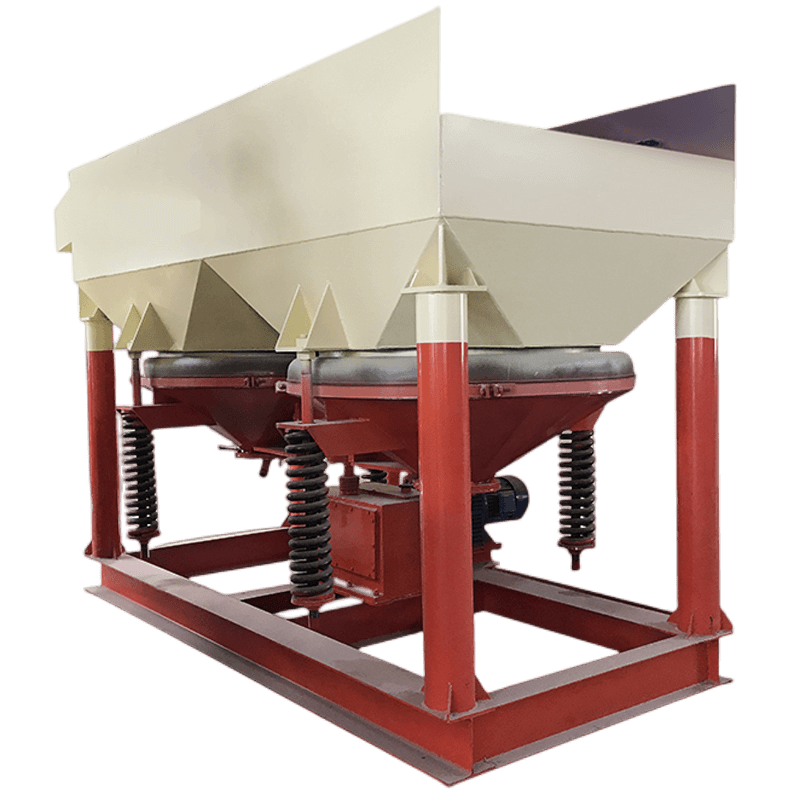

To operate the jigger, it is necessary to have a detailed understanding and mastery of how the jigger operates in the process, the factors affecting the sorting effect of the jigger, the mechanical structure and the role of each component, as well as the evaluation and identification of the sorting effect.

Jigger Operating Techniques

The task of operating a jigger is to create a good, stable process condition, properly loose jigging bed with the right mix of wind and water. The hallmark of this bed is not what the total bed thickness is, but how thick the regulated control heavy bed thickness should be. According to the problems existing in the operation of some plant jigger, the first one is to use enough wind, the second one, if there is a rewash situation, to go to the rewash of the middle coal discharge stable discharge enough, if there is no rewash, then according to the quality of the product requirements, the reasonable organization of the discharge.

In the operation of the jigger, the principle to be followed should be less water, more wind, and the processing capacity should be as large as possible under the possible conditions. In addition, the side layer of the heavy bed should be appropriately thin, because this is favorable to improve the handling capacity of the jigger, to ensure that the bed is reasonably loose, to ensure that a good sorting effect is also favorable.

Conditions to be created for jigger operation

bed level

Bed state mainly refers to the thickness and looseness of the bed. In general, the bed looseness is increased, and the stratification speed can be accelerated; but at the same time, it also increases the influence of particle size and shape on the stratification process. So the sorting is not graded or wide-grained coal, the bed looseness should be smaller appropriate, generally between 0.4 ~ 0.55 coal classification into the selection (mainly refers to the lump coal), in order to improve the productivity of the jigger, can be appropriate to improve the bed looseness, generally between 0.5 ~ 0.55. The speed of horizontal movement of the bed must be adapted to the speed of bed stratification according to density, which determines the separation of materials that have been stratified fast or slow. Can be controlled by adjusting the inclination angle of the sieve plate and the amount of wind and water. For coal selection, sorting lump coal, H = 5.10dmax; sorting end coal, then H = 10.20dmax; sorting 50mm or less ungraded coal elbow, bed thickness is generally 400-500mm.

Controlled feeding

For jigger, controlling the quality and quantity of incoming materials can ensure the stability of the sorting process, reduce the phenomenon of equipment overload or underload, improve the sorting efficiency and reduce the loss of coal in the gangue. Before the selection of the nature of the feed material homogenization, feed rate uniformity, along the width of the jigger feed, the material should be evenly distributed, for the stability of the jigging bed provides a reliable guarantee. Pay attention to the flushing water that accompanies the material feeding, must make the raw coal pre-wetting. Especially not graded into the selection, pulverized coal content is more important.

Air and water volume

The airflow is adjusted according to the required bed looseness. The air volume of the first section of the jigging chamber is larger than that of the second section. The air volume of each section of each chamber decreases sequentially from the feed to the overflow weir, but sometimes in order to strengthen the suction sipping effect of the middle chamber of the second section (middle coal section) and to strengthen the sieving process of the fine gangue through the screen, compared with the other chambers, the air volume can be increased appropriately.

Give into the jigger water from two aspects, one is with the material together with the rushing water (feed water), the second is from the sieve continuously or intermittently replenished under the sieve water (top water). Flushing water (ore water) is mainly used to pre-wet coal or ore to facilitate uniform and continuous to the section. The amount of water is generally not too large, the amount of raw materials to be able to feed the mouth of all wetting limit. For coal jigger, the amount of flushing water accounted for about 20% to 30% of the total water; for mining jigger, the feed water according to the concentration of the calculation is generally not more than 20% to 25%. The role of the water under the sieve is mainly to supplement the shortage of water under the sieve, reduce the liquid level difference between the jigging chamber and the air chamber at work, thus increasing the effective pressure of the compressed air inside the air chamber. The rising flow rate formed by the top water under the sieve is very small, about in the range of 0.5 ~ 1.0 cm / s, will not significantly change the large flow rate of pulsating water rising and falling.

Emissions of heavy products

Be sure to make the discharge rate of heavy products and bed stratification speed and gangue (or coal) layer of the horizontal movement speed compatible. The experience of many coal processing plants that, under the premise of ensuring that the loss of fine coal in the gangue product does not exceed the prescribed target, the discharge of heavy products in the gangue section should be preferable to more good, that is, the amount of gangue discharged should account for the total amount of gangue in the feed of 70% to 80%.

Vertical gate opening height, about 1.5 ~ 2 times the gangue, the application of buoy detection device, should be correctly adjusted buoy density, so that the actual density of the buoy than the section of the density of the sorting of the low 0.1 ~ 0.15g / cm3 or so, the volume of the buoy its density can be adjusted lower; volume of the buoy, the density of the small buoy, the density can be adjusted higher. The thickness of the heavy product bed is thinned to a height close to the opening of the vertical gate, immediately stop discharging.

Treatment capacity of jigger

The processing capacity of the jigger is closely related to the nature of the feed material. For example, separation of metal ores, when dealing with coarse grains, easy to select (large density difference, medium density of the ore particles or hyphenated body less, low mud content) of the material, and the quality of the concentrate is not high (such as roughing), the processing capacity can be increased; on the contrary, it should be reduced to enter the jigger water from two aspects, one with the ore into the feed water, and the other is the sieve to add water.

* Feed water should not be too large, according to the concentration calculation generally does not exceed 20-25%.

* The water under the screen can be supplemented to adjust the looseness of the bed, and can be appropriately increased when dealing with narrow-grade raw materials, in order to improve the stratification speed.

FAQs

Jigger reclassification influencing factors

The effect of jigger re-election process is affected by many factors, the following are five of the main factors:

1.Ore properties: The physical and chemical properties of the ore have an important impact on the jigger re-election process. The density, particle size, hardness of the ore and the density difference between valuable minerals and veins will directly affect the sorting efficiency.

2.Water flow rate and flow rate:water is one of the key factors in the re-election sorting process. The adjustment of water flow rate and flow rate can affect the movement of ore in the jigger and separation efficiency. Appropriate water flow conditions can improve the effect of reelection and separation.

3.Jigger parameters: The design and operating parameters of the jigger, such as pulsation frequency, amplitude and slope, can affect the sorting effect. These parameters need to be adjusted according to specific ore properties and sorting objectives.

4.Equipment selection: Different types of jigger equipment, such as traditional manual jigger, automatic jigger or centrifugal jigger, are more advantageous for different types of ores and sorting tasks. The choice of equipment will directly affect the efficiency and cost-effectiveness of sorting.

5.Maintenance and operating techniques:Maintenance and operating techniques of a jigger are critical to its performance. Regular maintenance and proper operation will ensure stable operation and long-term benefits of the equipment.

The interaction between these factors makes the jigger re-sorting process require experienced operation and careful adjustment to achieve the best sorting results.