Jaw crushers are used in various industries to crush different types of materials, from rocks and minerals to demolition waste and concrete.

They are one of the most commonly used crushing equipment due to their ability to process large amounts of material efficiently. A jaw crusher consists of a fixed jaw plate and a movable jaw plate that move in an elliptical motion to compress the material against the fixed jaw.

This compression force breaks the material into smaller pieces that can then be further processed. In this guide, we will discuss how jaw crushers work and their applications in different industries.

What is a Jaw Crusher?

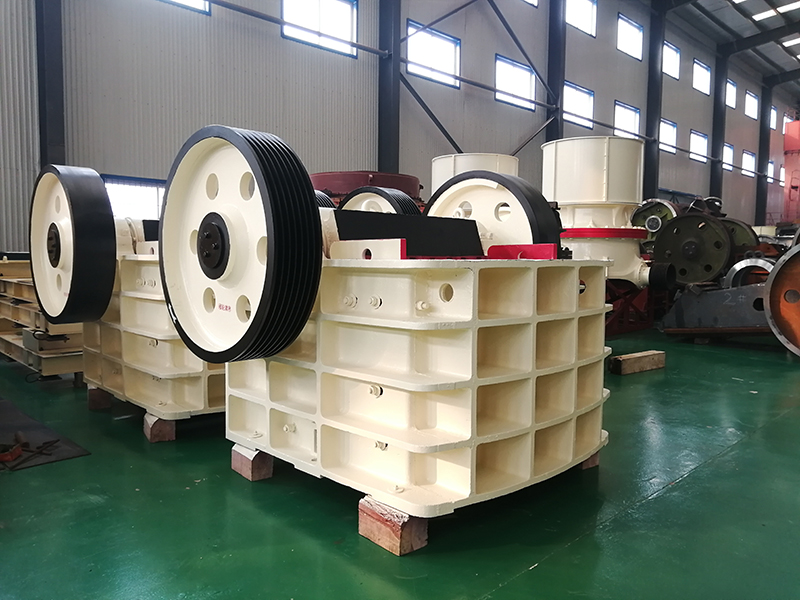

A jaw crusher is a type of primary crushing equipment that utilizes the compression force to break down materials. It consists of two jaws, one fixed and one movable, which are spaced apart at the top and narrow towards the bottom. The material to be crushed is fed into the chamber between these jaws and gets compressed as the jaws move closer together.

The movable jaw plate pivots on the bottom end of the crusher, creating an elliptical motion that applies pressure to the material. This crushing action is powered by a motor, which drives a flywheel that helps in maintaining the momentum of the moving jaw.

Jaw crushers come in various sizes and configurations, with different capacity and power requirements. They can also be customized for specific applications, such as mining or recycling. Additionally, they can have different types of crushing chambers, such as single or double toggle, depending on the type of material being processed.

Also, jaw crushers can be equipped with different types of features, such as hydraulic release systems and adjustable settings, to optimize the crushing process according to the specific material and intended use. In the following sections, we will discuss in detail how jaw crushers work and their various applications in different industries.

How Do Jaw Crushers Work?

As mentioned earlier, jaw crushers work by compressing materials between two jaws, one fixed and one movable. This compression force is created by the movement of the movable jaw against the fixed jaw.

When the material enters the crushing chamber, it gets crushed between the two jaws as they move closer together. The size of the crushed material depends on the gap between the jaws, which can be adjusted by using a toggle plate or hydraulic system.

The crushed material then falls down through the bottom of the chamber, where it can be further processed or collected. The elliptical motion of the movable jaw also helps in preventing any clogging or jamming of materials.

Jaw crushers are designed to handle a wide range of materials, from soft and abrasive to hard and brittle. They are commonly used in the mining, construction, and recycling industries due to their high efficiency and versatility.

Also, jaw crushers can be used for both primary and secondary crushing, making them a popular choice for various applications. In the next section, we will discuss some of the industries where jaw crushers are commonly used.

Applications of Jaw Crushers

Jaw crushers have a wide range of applications in different industries due to their ability to process various types of materials. Some of the industries where jaw crushers are commonly used include mining, construction, recycling, and demolition.

In the mining industry, jaw crushers are used for crushing large rocks and ores into smaller pieces that can be further processed. They are also used in stone quarries to break down larger stones into more manageable sizes for transportation.

In the construction industry, jaw crushers are used to crush concrete and other construction materials into smaller pieces that can be reused as building materials. They are also commonly used in road construction projects to break down rocks and gravel for use in the asphalt.

Jaw crushers are also widely used in the recycling industry, where they help process demolition waste and recycled concrete. They can efficiently break down these materials into smaller sizes to be reused in new construction projects.

Lastly, jaw crushers are also used in the demolition industry to break down buildings and structures into smaller pieces for easier disposal or recycling. This makes them an essential tool for various industries, contributing to their widespread use and importance.

Is a Jaw Crusher Right for Your Business?

Whether a jaw crusher is the right choice for your business depends on various factors. Firstly, it is important to consider the type of material you need to process and whether a jaw crusher is suitable for that particular material.

You should also take into account the size and capacity requirements of your business. Depending on the amount of material you need to process, you may need a larger or smaller jaw crusher with different features and settings.

Additionally, the cost and maintenance requirements of a jaw crusher should be considered. While they are efficient and versatile machines, they do require regular maintenance to ensure optimal performance.

Lastly, it is essential to research and compare different models and brands of jaw crushers to find the one that best suits your business needs and budget. Plus, consulting with industry experts can also help you make an informed decision.

Should You Invest in a Jaw Crusher?

Investing in a jaw crusher can bring a range of benefits to your business. They offer high efficiency and versatility, making them suitable for various applications and materials.

Plus, they have lower operating costs compared to other types of crushing equipment, such as cone crushers. And with regular maintenance, they can have a longer lifespan, providing a good return on investment.

Furthermore, having a jaw crusher can also improve the overall production process in your business. They can help in reducing material handling and transportation costs, as well as speeding up the crushing process for increased productivity.

However, it is crucial to carefully consider all factors before making any significant investments. Conducting thorough research and consulting with experts can help you determine if a jaw crusher is the right choice for your business and its specific needs. Ultimately, with the right jaw crusher, you can improve your operations and achieve greater success in your industry.

Are Jaw Crushers the Best Choice for Primary Crushing?

Jaw crushers are commonly used as primary crushers in various industries, but is it always the best choice? The answer depends on your specific needs and materials.

For instance, some materials may be better suited for other types of crushing equipment, such as impact or cone crushers. Also, depending on the size and capacity requirements, a jaw crusher may not be the most efficient option for primary crushing.

However, in many cases, jaw crushers are considered the best choice for primary crushing. They offer high reduction ratios and can handle large feed sizes, making them suitable for heavy-duty applications.

Furthermore, with advancements in technology, some jaw crushers now come with features like hydraulic settings and automatic tramp iron release, making them even more efficient and easier to use.

Ultimately, the best choice for primary crushing will depend on your specific needs and materials. It is essential to carefully evaluate all options and consider factors like capacity, efficiency, and cost before deciding on the type of crushing equipment for your business.

Mistakes to Avoid When Choosing a Jaw Crusher

Choosing the right jaw crusher for your business is crucial, but it can be easy to make mistakes during the selection process. Here are some common mistakes to avoid when choosing a jaw crusher:

- Not considering the type of material: As mentioned earlier, not all materials are suitable for crushing with a jaw crusher. It is essential to consider the type of material you need to process before choosing a jaw crusher.

- Not evaluating capacity requirements: Another mistake is not considering the required capacity for your business. A jaw crusher with insufficient capacity can lead to production delays and decreased efficiency.

- Ignoring maintenance and operating costs: While jaw crushers have lower operating costs compared to other types of crushing equipment, they do require regular maintenance. It is vital to consider these costs when selecting a jaw crusher.

- Not consulting with experts: Choosing a jaw crusher without seeking advice from industry experts can be a costly mistake. Experts can provide valuable insights and recommendations based on your business needs and goals.

- Not comparing different models/brands: Finally, not researching and comparing different jaw crusher models and brands can result in selecting a subpar machine that may not meet your needs. It is crucial to evaluate all options carefully before making a decision.

By avoiding these mistakes and thoroughly considering all factors, you can ensure that you choose the right jaw crusher for your business. This will lead to improved efficiency, productivity, and overall success in your industry.

Does Your Business Need a Jaw Crusher?

As discussed, jaw crushers offer many benefits and are suitable for various industries. But does your business really need one? The answer depends on several factors.

Firstly, if your business deals with materials that require primary crushing to achieve the desired size, then a jaw crusher may be necessary. Additionally, if your business handles large amounts of material and needs a machine with high capacity, then a jaw crusher could be the right choice.

Moreover, if your business is looking to reduce operating costs and improve overall production processes, investing in a jaw crusher can bring significant returns. However, it is essential to carefully consider all factors like material type, required capacity, and budget before making a decision.

Furthermore, if your business is expanding or has plans for growth in the future, a jaw crusher can support this by providing reliable and efficient crushing capabilities.

Tips for Choosing the Right Jaw Crusher

Choosing the right jaw crusher can have a significant impact on your business’s success. Here are some tips to help you make an informed decision:

- Consider the material: Make sure to choose a jaw crusher that is suitable for the type of material you need to process.

- Evaluate capacity requirements: Determine how much material you need to process and select a jaw crusher with enough capacity to meet your needs.

- Think about future growth: If your business is expanding or has plans for growth, select a jaw crusher that can support this growth.

- Research and compare different models/brands: Look into various jaw crusher models and brands to find the best one for your specific needs. Consider factors like features, performance, and cost.

- Consult with experts: Seek advice from industry experts to get a better understanding of your options and make an informed decision.

- Consider maintenance and operating costs: Factor in the maintenance and operating costs when selecting a jaw crusher. This will help you choose a machine that is cost-effective in the long run.

By keeping these tips in mind and carefully evaluating all options, you can choose the best jaw crusher for your business needs. This will lead to increased efficiency, improved productivity, and overall success in your industry.

FAQs

Are jaw crushers suitable for all types of materials?

No, some materials may be better suited for other types of crushing equipment. It is essential to consider the type of material you need to process before choosing a jaw crusher.

What factors should I consider when choosing a jaw crusher?

Some crucial factors to consider include the type of material, required capacity, maintenance and operating costs, future growth plans, and consulting with industry experts.

Can a jaw crusher help reduce operating costs for my business?

Yes, in most cases, investing in a jaw crusher can lead to reduced operating costs due to its lower energy consumption and maintenance requirements compared to other types of crushing equipment. However, it is essential to consider all factors before making a decision.

Conclusion

Choosing the right jaw crusher for your business is a crucial decision that can impact your success. It is essential to carefully consider factors like material type, capacity requirements, and budget before making a selection. Additionally, consulting with industry experts and comparing different models/brands can help you make an informed decision.

Remember to avoid common mistakes like not considering material type or capacity requirements, ignoring maintenance and operating costs, and not seeking expert advice. With the right jaw crusher, you can achieve efficient and cost-effective primary crushing, leading to improved production processes and overall success in your industry.