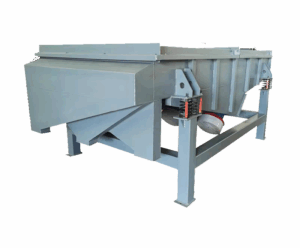

In industrial production, linear vibrating screen as an important screening equipment, widely used in mining, metallurgy, chemical industry, food and other fields. Through the vibration generated by the material will be screened, and the amplitude size is one of the key factors in determining the screening effect. The appropriate amplitude can make the material on the screen surface to achieve efficient stratification and permeability screening, improve screening efficiency and processing capacity; on the contrary, the amplitude is too large or too small will affect the screening quality, and may even cause damage to the equipment. Therefore, mastering the adjustment method of linear vibrating screen amplitude size and the precautions in the adjustment process is of great significance to ensure the normal operation of the equipment and production efficiency.

一.The influence factors of linear vibrating screen amplitude

1.Vibration motor parameters

vibration motor is the core component of linear vibrating screen vibration, and its excitation force size, speed and other parameters directly affect the amplitude of linear vibrating screen. The larger the excitation force, the larger the amplitude of the linear vibrating screen under the same conditions; motor speed is also related to the amplitude of the existence of a certain correlation, usually changes in speed will change the vibration frequency, which affects the movement of the material on the screen surface and the performance of the amplitude.

2.Counterweight configuration

The counterweight on the vibration motor is an important means of adjusting the amplitude. By changing the number, weight and installation position of the counterweight block, the vibration motor can be adjusted to the size and direction of the vibration force, so as to achieve the adjustment of the amplitude of the linear vibrating screen. The unreasonable configuration of the counterweight block will lead to unstable amplitude or can not reach the expected value.

3.Screen structure and material

The overall structural design of the linear vibrating screen, the screen frame material and the stiffness of the support spring and other factors will also have an impact on the amplitude. Solid and stable structure and appropriate stiffness of the support spring can ensure the effective transmission of vibration energy, help to maintain a stable amplitude; while the poor material or structural design of the irrational sieve machine, in the vibration process there may be excessive energy loss and other problems, affecting the amplitude size and stability.

4.The nature of the material

screened material particle size, humidity, density, viscosity and other properties are different, the required optimal amplitude is also different. For example, for smaller particle size, humidity or viscous materials, usually need a smaller amplitude to avoid material blockage sieve holes; for larger particle size, density of materials, may need a larger amplitude to promote the movement of the material and screening.

二.The adjustment method of linear vibrating screen amplitude size

1.Through the vibration motor counterweight block adjustment

Determine the direction of adjustment: before adjusting, you need to observe the screening effect of the linear vibrating screen, and judge whether you need to increase or reduce the amplitude. If the material on the screen surface movement speed is too slow, screening efficiency is low, you may need to increase the amplitude; if the material jumping is too violent, or even part of the material jumps out of the screen surface, you may need to reduce the amplitude. Adjust the number of counterweights: increasing the number of counterweights can increase the vibrating force of the vibrating motor, thus increasing the amplitude of the linear vibrating screen; decreasing the number of counterweights will reduce the vibrating force and amplitude. When increasing or decreasing the number of counterweights, it is necessary to pay attention to keeping the number and weight of counterweights on both sides of the vibrating motor symmetrical, in order to avoid the imbalance that leads to abnormal vibration of the equipment, noise and damage. Changing the position of the counterweight block: besides adjusting the quantity, the amplitude can also be adjusted by changing the installation position of the counterweight block on the eccentric block of the vibration motor. Generally speaking, moving the counterweight block away from the centre of the vibration motor shaft can increase the eccentric distance, thus increasing the excitation force and amplitude; on the contrary, moving the counterweight block closer to the centre of the shaft will reduce the amplitude. When adjusting the position, the same should be ensured that both sides are adjusted symmetrically. Gradual fine-tuning: in the process of adjusting the counterweight block, don’t make a one-time large-scale adjustment, should gradually increase or decrease the number of counterweight block, change the position, start the equipment to observe the screening effect and amplitude change after each adjustment, and then make the next adjustment according to the actual situation until reaching the suitable amplitude.

2.Adjust the speed of the vibration motor

Choose a suitable speed regulation: some linear vibrating screens are equipped with adjustable speed vibration motors, and the common speed regulation methods include frequency conversion, electromagnetic speed regulation, etc. The frequency conversion is achieved by changing the power supply, and the speed of the vibration motor is adjusted by changing the power supply. Frequency conversion speed regulation is to adjust the motor speed by changing the power supply frequency, which has the advantages of wide speed range, high precision, energy saving, etc. Electromagnetic speed regulation is to use electromagnetic clutch to achieve speed regulation. Adjusting the speed slowly: when adjusting the speed, it should be done slowly to avoid the impact on the equipment caused by the sudden change of the speed. Gradually increase or decrease the rotational speed, and at the same time observe the amplitude change of the linear vibrating screen and the material screening situation. Generally speaking, increasing the rotational speed will increase the vibration frequency and may increase the amplitude to a certain extent, but the specific effect should be determined according to the actual situation of the equipment and materials; reducing the rotational speed may reduce the amplitude. Comprehensive consideration of other factors: when adjusting the rotational speed, not only should we pay attention to the change of amplitude, but also consider the trajectory of the material on the screen surface, screening efficiency and other factors. If the rotational speed is too high, although the amplitude may increase, but the residence time of the material on the screen surface is too short, which is not conducive to the stratification and permeability screening; too low a rotational speed may lead to insufficient movement of the material, affecting the screening effect.

3.Replacement of the support spring

Assessment of the spring state: the support spring may be fatigued, deformed, elasticity weakened and other problems after long-term use, affecting the amplitude stability of the linear vibrating screen. If the amplitude of the screen machine is found to be unstable or abnormal, it is necessary to check the state of the support spring and judge whether it needs to be replaced. Choose the right spring: when replacing the support spring, choose a spring that matches the specifications, material and stiffness of the original spring. The stiffness of the spring has a direct effect on the amplitude. A spring with greater stiffness provides more stable support and helps to maintain a larger amplitude, while a spring with less stiffness may reduce the amplitude. When selecting springs, the overall structure and design requirements of the equipment should also be considered. Install the springs correctly: when installing the support springs, make sure that the springs are installed in the exact position and the force is uniform. Improper installation may lead to vibration imbalance of the screen machine, affecting the amplitude and normal operation of the equipment. After installation, the screen machine should be debugged to check whether the amplitude reaches the expected effect.

三.The attention of adjusting the amplitude

1.Equipment protection

Avoid over-adjustment: when adjusting the amplitude, avoid excessive increase in the counterweight block or over-adjustment of the vibration motor speed, so as not to make the equipment to withstand excessive loads, resulting in overheating of the vibration motor, deformation of the sieve frame, damage to the support springs and other problems, which will Shorten the service life of the equipment. After each adjustment, observe the running status of each part of the equipment to ensure that the equipment is normal. Regular inspection and maintenance: after adjusting the amplitude, the linear vibrating screen should be comprehensively inspected, including whether the wiring of the vibrating motor is loose, whether the connecting parts of the screen frame are firm, and whether the support spring is abnormal. At the same time, in accordance with the maintenance requirements of the equipment, lubrication, cleaning and other maintenance work on a regular basis to ensure that the equipment is in good operating condition. Record the adjustment: Make detailed records of the process and results of each amplitude adjustment, including the time and method of adjustment, the size of the amplitude before and after the adjustment, and information on the operating condition of the equipment. These records help to analyse the subsequent operation of the equipment, sum up the adjustment experience, for future equipment maintenance and adjustment to provide reference.

2.Production Adaptation

Consideration of material characteristics: As mentioned above, different materials have different properties, when adjusting the amplitude, we should fully consider the material’s particle size, humidity, density, viscosity and other factors, and choose the appropriate amplitude according to the characteristics of the material. In the replacement of screening materials, also need to re-evaluate and adjust the amplitude, in order to ensure the best screening effect. Observe the production effect: after adjusting the amplitude, we should continuously observe the movement state of the material on the screen surface and the screening effect, including the stratification of the material, the permeability rate, the processing capacity and other indicators. If the screening effect is found to be unsatisfactory, it is necessary to analyse the reasons in time, further adjust the amplitude or check whether there are problems in other aspects of the equipment. with the production process: the screening process of the linear vibrating screen is usually a part of the whole production process, and when adjusting the amplitude, it is necessary to consider the cooperation with other production equipment and process links. For example, to ensure that the particle size of the screened material meets the requirements of the subsequent production process, to avoid improper adjustment of the amplitude to affect the smooth progress of the entire production process.