In many aspects of industrial production, material crushing is a basic and critical process. Jaw crusher, as a classic and widely used crushing equipment, plays an irreplaceable role in many fields. In-depth understanding of the application of the jaw crusher and how to make a reasonable selection of equipment, for related enterprises to improve production efficiency, reduce costs and ensure product quality is of great significance.

一.The working principle of jaw crusher

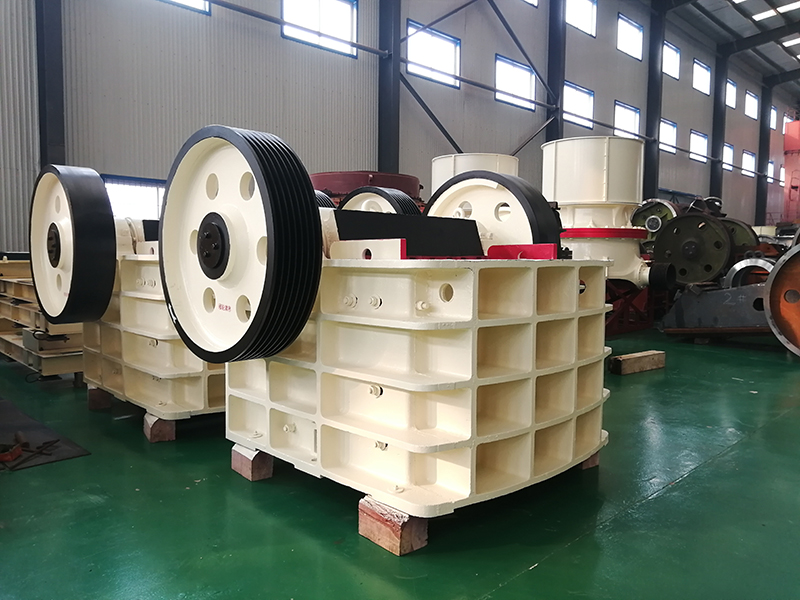

When the jaw crusher is working, the motor drives the eccentric shaft to rotate through the pulley, so that the movable jaw is close to and leaves the fixed jaw periodically. In this process, the material enters the crushing chamber and is subjected to multiple forces such as extrusion, rubbing and crushing by the movable jaw and the fixed jaw. With the continuous movement of the movable jaw, the material is gradually crushed, from large particles to small particles, until it reaches the appropriate particle size and discharged from the discharge port, completing the whole crushing process. This way of working makes the jaw crusher able to adapt to a variety of hardness and nature of the material crushing needs.

二.The jaw crusher application scene

1.Mining field

Ore mining and primary crushing: In mining, jaw crusher is the preferred equipment for primary crushing. For example, in the mining process of iron ore, copper ore and other types of metal ores, the large pieces of raw ore extracted from the ground need to be crushed by the jaw crusher first. It can break the huge ore blocks into smaller particle size, convenient for subsequent transport, screening and further processing and refining. Take a large open-pit iron ore mine as an example, a large amount of iron ore mined every day, through the jaw crusher for primary crushing, and then transported to the subsequent crushing and beneficiation process, which greatly improves the production efficiency of the entire mine.

Non-metallic ore processing: Jaw crusher is also indispensable for the processing of limestone, dolomite, quartzite and other non-metallic ores. Limestone is an important raw material for the production of cement, through the jaw crusher will be large limestone crushed into the appropriate size, and then grinding and other subsequent processes, in order to make cement products. In the processing of quartz stone, the crushed quartz stone can be used in glass manufacturing, electronic industry and other fields, jaw crusher for these subsequent industries to provide the basic raw materials to meet the particle size requirements.

2.Construction material industry

Aggregate production: A large amount of sand and gravel aggregate is needed in construction projects such as roads, bridges and real estate. Jaw crusher can crush the mined granite, basalt, sandstone and other large stones into sand and gravel aggregates that meet the requirements. For example, in the construction of highways, a large number of stones of different specifications are needed for the laying of road base and surface layers. Jaw crusher is able to produce various specifications of aggregates according to the needs of engineering design by adjusting the shape of crushing chamber and the size of feed opening to meet the needs of different engineering projects.

Construction waste recycling: With the rapid development of urban construction, the amount of construction waste generated is increasing. Jaw crusher plays an important role in the field of construction waste recycling, which can crush waste concrete, bricks, asphalt and other construction materials, and turn these wastes into recycled aggregates. These recycled aggregates can be used to produce recycled concrete, bricks and other building materials, to achieve the recycling of resources, which not only solves the problem of waste disposal, but also reduces the dependence on natural aggregates, in line with the concept of sustainable development.

3.Road and railway construction

Crushed stone production: The construction of road base and road surface of highways and railways requires a large amount of crushed stone. Jaw crushers are used to produce these aggregates, providing the necessary material support for infrastructure construction. For example, in the laying of railway beds, crushed stone of a specific size and strength is required. The jaw crusher is able to crush suitable rock raw materials into crushed stone that meets the requirements to ensure the stability and load-bearing capacity of the railway bed.

Ballast Stone Processing: Ballast stone laid under the railway track also needs to be processed by jaw crusher. Ballast stone has strict requirements on particle size, shape and hardness, etc. Through reasonable selection and adjustment, the jaw crusher can produce products to meet the standard of railway ballast stone, ensuring the safe operation of railway tracks.

4.Metallurgical and chemical industry

Ore pretreatment: In the metallurgical industry, various ores used for smelting need to be crushed first. Jaw crusher is used for preliminary crushing of iron ore, copper ore and other ores to provide raw materials with suitable particle size for the subsequent smelting process. For example, in iron and steel smelting, iron ore crushed by jaw crusher is easier to be sintered, pelletised and other pre-treatment processes to improve smelting efficiency and product quality.

Chemical raw material crushing: In the chemical industry, many raw materials need to be crushed before chemical reaction or further processing. For example, when limestone is used to produce calcium carbide, soda ash and other chemical products, it needs to be crushed by jaw crusher first, so that its particle size meets the requirements of the chemical production process, which promotes the smooth progress of the chemical reaction and improves the output and quality of chemical products.

5.Cement raw material crushing

In the process of cement production, raw materials such as limestone, clay, iron ore and coal need to be crushed. Jaw crusher, as an important equipment for cement raw material crushing, can crush large raw materials into smaller particles for subsequent grinding in the mill. For example, in a large cement plant, a large amount of limestone raw materials need to be processed every day, the jaw crusher, through efficient crushing operations, provides raw materials with uniform particle size for the subsequent process of cement production, ensuring the continuity and stability of cement production.

6.Quarry

In the quarry, jaw crusher is used for primary crushing of large rocks. The rocks extracted from the quarry are initially crushed by the jaw crusher and then further processed into stone products with different specifications according to the market demand, which are used for sales in the fields of construction, roads and so on. It is the key equipment in the production process of the quarry, and its crushing efficiency and product quality directly affect the economic benefits of the quarry.

三.Jaw crusher equipment selection

1.Production capacity

Determine the production demand: when choosing a jaw crusher, users should firstly define their own production scale and production requirements. If it is a small construction aggregate processing plant, the daily output demand may be in the tens to hundreds of tonnes; while for large mines or cement plants, the daily output demand may reach thousands of tonnes or even tens of thousands of tonnes. According to the actual production demand, the preliminary screening of equipment models that can meet the production capacity.

Consider the potential of the equipment: in addition to meet the current production demand, should also take into account the possible future expansion of production capacity. Select equipment with a certain production potential, when the business growth, the equipment can be properly adjusted or upgraded to meet the higher production requirements, to avoid the need to replace the equipment due to insufficient capacity, resulting in unnecessary cost waste.

2.Feed size

Measure the material size: accurately measure the maximum size of the material to be crushed, and select a jaw crusher with a feed opening size larger than the maximum size of the material. For example, if the size of the largest piece of material is 500mm, then the width and length of the feed opening should be selected to accommodate this size of material to ensure that the material can enter the crushing chamber for crushing smoothly, and to avoid the material clogging due to the small feed opening, which affects the production efficiency.

Reserve a certain margin: In actual production, the particle size of the material may have certain fluctuations. In order to ensure the stable operation of the equipment in various situations, a certain margin should be reserved when choosing the equipment with appropriate feed size. Generally speaking, the size of the feed opening should be 10% – 20% larger than the maximum particle size of the material to cope with changes in the particle size of the material.

3.Discharge size

Comparison table: Different models of jaw crusher have different range of discharge size. Users need to choose the equipment that can produce products with the required particle size according to their own requirements for the product size and the equipment parameter table. For example, if you need to produce stones with a particle size below 50mm, you should choose a jaw crusher model with a discharge size range that meets this requirement.

Consideration of adjustability: Some production scenarios may have diversified demands on the discharge size, and then priority should be given to selecting equipment with a larger adjustable range of discharge size. By adjusting the size of the discharge opening and other parameters of the equipment, the discharge size can be flexibly controlled to meet the requirements of different customers or production processes on the particle size of the product.

With its unique working principle and wide applicability, jaw crusher plays an important role in many fields such as mining, building materials, road and railway construction, metallurgy and chemical industry, cement and so on. In the process of equipment selection, it is necessary to comprehensively consider a number of factors, such as production capacity, feed size, discharge size, cost-effective, as well as equipment quality and reliability. Only by choosing the right jaw crusher equipment, enterprises can improve efficiency in the production process, reduce costs, ensure product quality, so as to occupy an advantageous position in the fierce market competition. With the continuous progress of science and technology and the increasingly diversified needs of industrial production, the jaw crusher will also continue to innovate and develop to provide stronger support for the development of various industries.