In industrial production, LG chain feeders, reciprocating feeders, mining feeders and heavy-duty vibrating feeders have their own position. They are both different and have their own advantages in terms of applicable materials, performance characteristics, application scenarios, etc . Choosing the right feeder is crucial for improving production efficiency and reducing production costs.

LG chain feeders: the exclusive companion for mixed loose materials

LG type chain feeder is suitable for many industries such as coal, cement, metallurgy and chemical industry etc. It is especially good at handling mixed loose materials with particle size between 0 – 100 mm. In the coal industry, it is able to transport the mined coal evenly from the storage silo to the subsequent processing equipment, ensuring a smooth coal processing process. The coal is transported steadily through the chain feeder, and is accurately fed into the crusher and other equipment, laying the foundation for the subsequent washing, coking and other processes. In cement production, it also plays a key role in conveying limestone, clay and other raw materials to the mill for grinding in proportion to provide a stable supply of materials for cement production.

In practical application, LG type chain feeder is often used in conjunction with jigger, and this combination is called the ‘golden partner’ in the field of coal beneficiation. In the coal beneficiation plant, the chain feeder feeds the raw coal into the jigger uniformly and equally along the width of the jigging chamber. According to the different quality of the incoming coal, the operator can easily adjust the size of the feeder’s feeding volume. When the coal quality is good, increase the feeding volume appropriately to give full play to the processing capacity of the jigger; when the coal quality is poor, reduce the feeding volume to ensure the washing effect of the jigger. This precise adjustment greatly improves the washing effect of the jigger, so that the quality and recovery rate of fine coal can be significantly improved, which brings higher economic benefits for the enterprise.

Reciprocating feeder: a versatile player in many industries

Reciprocating feeder is a kind of material conveying equipment widely used in industrial production. Its working principle is based on the drive of the motor, and the power is transmitted to the feeding device through the gearbox and transmission device, so as to realise the transmission of materials. In actual operation, the motor drives the transmission gear to rotate, and then drives the feeding mechanical device to do reciprocating motion, and accurately conveys the material to the specified position.

With the remarkable features of fast feeding speed and high feeding accuracy, reciprocating feeder is widely used in many industries such as automobile manufacturing, electronic equipment, food processing and so on. In the field of automotive manufacturing, it can produce a variety of automotive parts, such as engine parts, body panels, etc., quickly and accurately transported to the various assembly stations, a strong guarantee of the efficient operation of the automotive production line. In the production of electronic equipment, for those small size, high precision requirements of electronic components, such as chips, resistors, capacitors, etc., the reciprocating feeder can rely on its high-precision feeding performance, these components accurately delivered to the processing position for the high-quality production of electronic products to provide a solid guarantee. In the food processing industry, it can be used to convey all kinds of food raw materials and finished products, such as flour, candy, biscuits and so on. In the biscuit production line, the reciprocating feeder quickly conveys the moulded biscuit blanks to the baking equipment, and after baking, it conveys the finished biscuits to the packaging link, which greatly improves the efficiency and quality of food processing.

Reciprocating feeder is suitable for conveying granular and lumpy materials, such as ore, coal, grain and so on. In mining, it can convey the mined ore from the mine to the ore dressing plant for subsequent processing; in grain storage and processing, it can convey grain from the warehouse to the processing equipment for grinding, processing and other operations . But it is not suitable for conveying concentrate powder and other powdery materials, this is because powdery materials are highly mobile, in the reciprocating feeding process is prone to dust, which will not only cause material waste, but also may be harmful to the working environment and the health of the operator.

Its structure is mainly composed of feeding part and control part. The feeding part contains feeding table, feeding beam and feeding device, among which the feeding device is the most critical, like the touch feeder head senses the position of the material through the sensor and then places it on the feeding frame. The control part is mainly composed of electrical control device and computer system, the electrical control device controls the movement of the feeding device, and the computer system regulates the operation of the whole equipment through algorithms and preset parameters. This structural design makes the reciprocating feeder structure is simple, easy to maintain, the operator without special training can easily start operating. Moreover, it is small in size and occupies little space, which makes it a very ideal material conveying equipment for those production environments with limited space.

Mining feeder: the main force of mining material conveying

Mining feeder, a material conveying equipment specially designed for the mining industry, plays a pivotal role in the fields of mining and ore processing.

In metal mines, ores mined from underground, such as iron ore, copper ore, lead and zinc ore, etc., will first be conveyed from the ore bin to the crusher for preliminary crushing through the mine feeder. Taking iron ore mining as an example, the mine feeder will evenly feed the iron ore lifted up from the mine into the jaw crusher, and the crushed iron ore will then enter the subsequent grinding, beneficiation and other processes. In the ore dressing plant, the mining feeder is used to mix and convey all kinds of dressing chemicals and ores in proportion to ensure the accuracy and efficiency of the dressing process. In the building materials industry, limestone, dolomite and other raw materials can not be separated from the delivery of mining feeder, which will convey these raw materials from the silo to the mill for grinding, providing basic raw materials for the production of cement, lime and other building materials. In the coal industry, whether it is the coal conveyance in underground coal mine or the raw coal processing in the ground coal processing plant, the mining feeder undertakes an important material conveying task, which conveys the coal from the coal mining face or the coal bunker to the transport equipment, and then transported to the washing plant for processing.

The performance characteristics of the mining feeder make a close connection between it and the applicable materials. Its excitation force is adjustable, and the operator can flexibly adjust the size of the excitation force according to the characteristics of the materials and conveying requirements. For larger particle size, higher hardness of the material, the appropriate increase in the excitation force, to ensure that the material is smoothly discharged from the silo and transported forward; for smaller particle size, viscous materials, it is appropriate to reduce the excitation force, to avoid the material in the process of transporting the situation of blockage or splash. The feature of smooth vibration enables the material to maintain a uniform flow rate in the conveying process and reduces the crushing and loss of the material. When conveying fragile ores, the smooth vibration can effectively reduce the crushing rate of ores and ensure the quality of products. Controllable feeding volume is also a major advantage of mining feeder, through the adjustment of vibration frequency, amplitude or conveying speed and other parameters, you can accurately control the feeding volume of materials to meet the needs of different production processes. In the beneficiation process, according to the grade of the ore and the amount of beneficiation chemicals added, precise control of the feeding amount of the ore, in order to ensure the stability and consistency of the beneficiation effect.

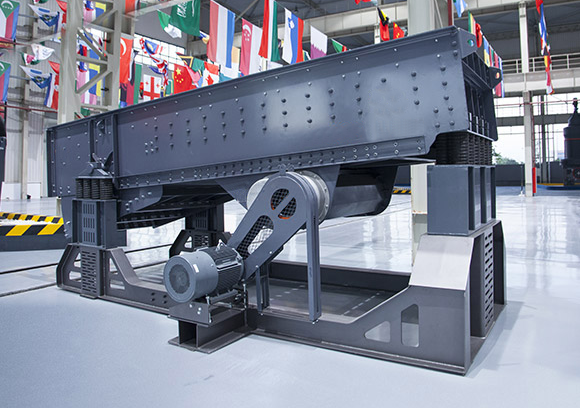

Heavy Duty Vibrating Feeder: A Powerful Enabler for Heavy Industrial Materials

Heavy-duty vibrating feeder, a large material conveying equipment specially designed to meet the needs of heavy industrial production, is widely used in many heavy industrial fields such as mineral processing, aggregate, glass, cement, chemicals, wood products and steel industry. With its strong conveying capacity and stable performance, it has become the key equipment for material conveying in heavy industry.

In the mineral processing industry, the raw ores extracted from mines, such as iron ore, copper ore, etc., are often large particles and high hardness, and need to be processed through multiple procedures to extract useful metals. Heavy-duty vibrating feeder plays an important role in this process, which can transport these large ores from the ore bin to the crusher and other subsequent equipment in an even and continuous manner.

In cement production, limestone, clay, iron ore and other raw materials need to be mixed in a certain proportion for grinding and calcination. Heavy vibrating feeder can accurately control the feeding amount of these materials to ensure that the proportion of various raw materials is accurate, so as to ensure the stable quality of cement.

In the iron and steel industry, sinter ore, coke and other materials are important raw materials for blast furnace ironmaking. Heavy vibrating feeder can transport these materials stably into the feeding system of blast furnace to ensure the continuous production of blast furnace. In the raw material workshop of the iron and steel plant, the heavy vibrating feeder conveys the stored sinter ore and coke to the belt conveyor continuously according to the production demand of the blast furnace, and then the belt conveyor conveys the materials to the blast furnace to ensure the smooth progress of the process of ironmaking in the blast furnace.

The reason why the heavy vibrating feeder can be competent in these heavy industrial fields for the heavy responsibility of material conveying is closely related to its own characteristics. It has a large processing capacity to meet the needs of large-scale production. In large-scale mining, tens of thousands of tonnes of ore need to be processed every day, the high capacity of the heavy vibrating feeder makes it possible to quickly transport the ore from the mining site to the beneficiation plant, which improves the production efficiency of the whole mine. Its precise feeding control is also a major advantage, through the adjustment of vibration frequency, amplitude and other parameters, can achieve accurate control of the material feeding volume, to meet the strict requirements of different production processes on the material ratio. In chemical production, the ratio of various raw materials directly affects the quality of the product, heavy-duty vibrating feeder accurate feeding function to ensure the stability of chemical production and product quality reliability. In addition, heavy vibrating feeder also has good environmental adaptability, can be in high temperature, high humidity, dust and other harsh working environment stable operation. In the production workshop of cement factory, the environment is full of a lot of dust, the closed structure and special dustproof design of heavy vibrating feeder can effectively prevent the erosion of dust on the equipment and ensure the normal operation of the equipment.