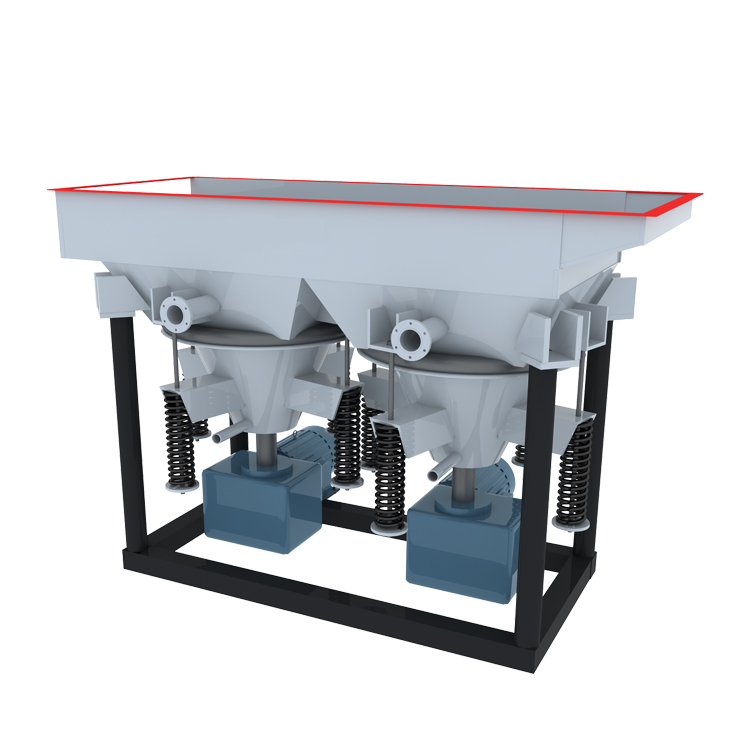

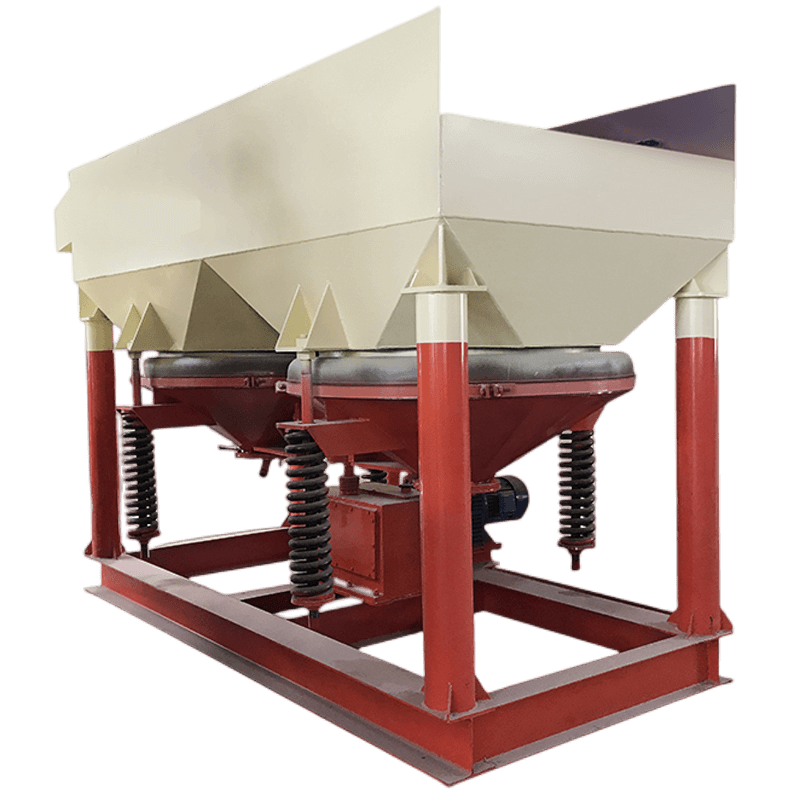

In the field of mineral processing, SKT series jigger has become the first choice of many mineral processing plants with its excellent performance and advanced technology.SKT series jigger is a kind of gravity beneficiation equipment, which makes use of the difference in settling speeds of minerals with different densities in the vertically alternating water flow to realise the separation of useful minerals and vein stones.

The structure design of SKT series jigger is exquisite and reasonable. It mainly consists of machine body, air valve system, screen plate, discharge device and water supply system. The machine body is usually made of strong metal materials to ensure that it can withstand great pressure and impact during long-term operation. The damper system is the key component to control the pulsation of water flow in the jigger. By precisely adjusting the air inlet and exhaust time of the damper, the ideal pulsation characteristics of water flow can be realised, which creates good conditions for the stratification and separation of minerals. The sieve plate plays the role of supporting the minerals and controlling the particle size, high quality sieve plate material and reasonable sieve hole size can help to improve the beneficiation efficiency and product quality. Discharge device is responsible for discharging the concentrate and tailings after sorting in time to ensure the continuity and stability of production. The water supply system provides stable water flow for the jigger to ensure the normal process of ore dressing.

Working Principle of SKT Series Jigger

Through the air valve to control the water flow periodic up and down pulsation, so that the raw coal in the pulsating water flow mainly according to the density of stratification, and then through the discharge mechanism to separate the stratified materials to achieve the purpose of sorting.

Specifically, after the raw coal enters the jigger, under the action of pulsating water flow, the gangue with large density gradually sinks to the bottom layer, the middle coal with moderate density is distributed in the middle layer, and the fine coal with small density is distributed in the upper layer. After stratification, the gangue located in the bottom layer enters the first discharge bin and is discharged by the discharge impeller; the middle coal and fine coal enter the second section of the jigger with the pulsating water flow to continue sorting, and after stratification, the middle coal located in the bottom layer enters the second discharge bin and is discharged by the discharge impeller; there is also a part of small particles of the gangue and the middle coal is discharged by the permeable sieve; the fine coal located in the upper layer is spilled out by the fine coal overflow port.

The water pulsation involved in the working process is generated by the washing water through the inlet and outlet of the numerically controlled dampers. This principle of operation enables the SKT series jigger to achieve effective separation of raw coal, which is suitable for easily selectable and moderately selectable coals.

During the jigging process, care must be taken to maintain the necessary looseness of the bed, which is a prerequisite for separation. If the bed looseness is insufficient, the ore particles are difficult to transfer each other, and the possibility of stratification is lost. In addition, the particle size and shape of the raw coal particles also have an effect on the stratification, especially in the period of the relative movement speed between the ore particles and the medium is large. The upward flow should have a large positive acceleration and a small negative acceleration, while the downward flow should have a small positive acceleration and a large negative acceleration. At the same time, the suction effect of the descending water flow can improve the jigging effect of the narrow level and ungraded ore particles, but the intensity and duration of the suction effect need to be selected according to the nature of the raw materials. For the separation of fine-grained raw coal, appropriately increasing the frequency of water movement can also improve the separation effect. Adding some high specific gravity fine ore particles in the bed also helps to improve the jigging effect of ungraded raw coal, but it may be necessary to readjust the jigger to strengthen the inhalation effect.

SKT series jigger has many advantages

It has high beneficiation efficiency and precision, and can effectively separate minerals with different densities and improve the grade and recovery rate of the ore. Secondly, this series of jigger has a large processing capacity, which can adapt to the demand of large-scale beneficiation production. In addition, the operation and maintenance of SKT series jigger is relatively simple and the running cost is low, which has good economy.

In practical application, SKT series jigger is widely used in the beneficiation of coal, metal ore and non-metal ore. In coal beneficiation, it can effectively remove the gangue in coal and improve the quality and calorific value of coal. In metal ore beneficiation, such as gold, copper and lead-zinc ores, SKT series jigger can separate useful metal minerals and provide high quality raw materials for subsequent smelting process. In non-metallic ore beneficiation, such as fluorite ore, barite ore, etc., this series jigger also plays an important role.

How to improve the sorting effect of SKT series jigging machine?

1.Optimise the feeding material: Ensure that the particle size composition of the feeding material is uniform and stable, and avoid excessive particle size differences and fluctuations. At the same time, control the feeding volume so that it is within the processing capacity of the jigger to ensure the normal stratification of the bed.

2.Adjust the damper parameters: Reasonably set the inlet and exhaust time, period and frequency of the damper to produce suitable water flow pulsation characteristics. Through test and experience, find the most suitable combination of damper parameters to process the current material.

3.Control bed thickness: maintain a proper bed thickness, too thick or too thin will affect the sorting effect. According to the nature of the material and sorting requirements, precisely adjust the bed thickness.

4.Adjust the water volume and water pressure: Reasonably control the water volume and water pressure of the top water and flushing water to ensure that the water flow is evenly distributed to provide good conditions for material stratification.

5.Regular maintenance and inspection: check the wear and tear of the screen plate regularly and replace the damaged screen plate in time to ensure the normal screening and stratification of materials. At the same time, the air valve, discharge device and other key components are maintained to ensure their normal operation.

6.Operator training: Improve the technical level and experience of the operators so that they can adjust the parameters of the jigger timely and accurately according to the material changes.

7.Improvement of raw coal pre-treatment: before entering the jigger, pre-treat the raw coal with appropriate crushing, screening and other pre-treatment, so as to improve the quality and uniformity of the raw coal.

8.Optimise the process: Combine with the whole ore dressing process, reasonably configure the equipment before and after the jigger, so that the material conveying and processing is smoother and the overall sorting effect is improved.

It should be noted that for different raw coal properties and beneficiation requirements, the specific measures to improve the sorting effect may be different. Therefore, in actual operation, it is necessary to find the most suitable solution through testing and continuous optimisation.

SKT series jigger maintenance and care methods:

1.Regular inspection:

Check the various parts of the jigger, including the body, air valve system, screen plate, discharge device, water supply system, etc., on a daily basis to see if there are any signs of looseness, wear and tear, deformation or damage.

Regularly check the transmission parts, such as belts, chains, couplings, etc., to ensure that they are properly tensioned and free from cracks or excessive wear.

2.Cleaning:

Clean the accumulated dust, debris and oil on the inside and outside of the jigger in a timely manner to prevent them from entering the inside of the equipment and causing wear and tear and malfunction.

Regularly clean the blockage on the screen plate to ensure that the screen holes are smooth to maintain normal screening effect.

3.Lubrication maintenance:

In accordance with the requirements of the equipment, lubricate the lubrication points regularly to ensure good operation of the moving parts and reduce wear and tear.

Pay attention to the use of suitable lubricating oil or grease, and ensure its quality and cleanliness.

4.Dampers system maintenance:

Regularly check the sealing and flexibility of the dampers to ensure that they work properly.

Clean the debris and dirt inside the dampers to prevent affecting the normal control of airflow.

5.screen plate replacement:

When the screen plate is seriously worn or damaged, replace the screen plate with a new one in time to ensure the sorting effect and normal operation of the equipment.

6.Discharge device maintenance:

Check the wear of the discharge impeller and repair or replace the worn parts in time.

Ensure that the transmission parts of the discharging device are normal, and adjust the discharging speed to match the sorting process.

7.electrical system inspection:

Regularly check whether the electrical connection is loose and whether the wires are broken to ensure the safe and stable operation of the electrical system.

8.regular maintenance:

According to the operating time and working intensity of the equipment, make regular major maintenance plan to carry out comprehensive inspection, maintenance and debugging of the equipment.

9.equipment shutdown maintenance:

If the jigger is out of operation for a long time, protective measures should be taken to protect the easy-to-corrode parts with oil and cover the key parts to prevent the intrusion of dust and moisture.

10.Record maintenance:

Establish detailed maintenance records, including information on maintenance time, maintenance content, replacement parts, etc., so as to track the maintenance history of the equipment and analyse the causes of failure.

Strictly following the above maintenance and repair methods can prolong the service life of SKT series jigger and improve the operation efficiency and sorting effect of the equipment.

With the continuous progress of science and technology and the continuous development of mineral processing technology, SKT series jigger is also constantly innovating and improving. In the future, we have reason to believe that SKT series jigger will play a more important role in the field of mineral processing and make greater contribution to the efficient use of mineral resources and sustainable development.