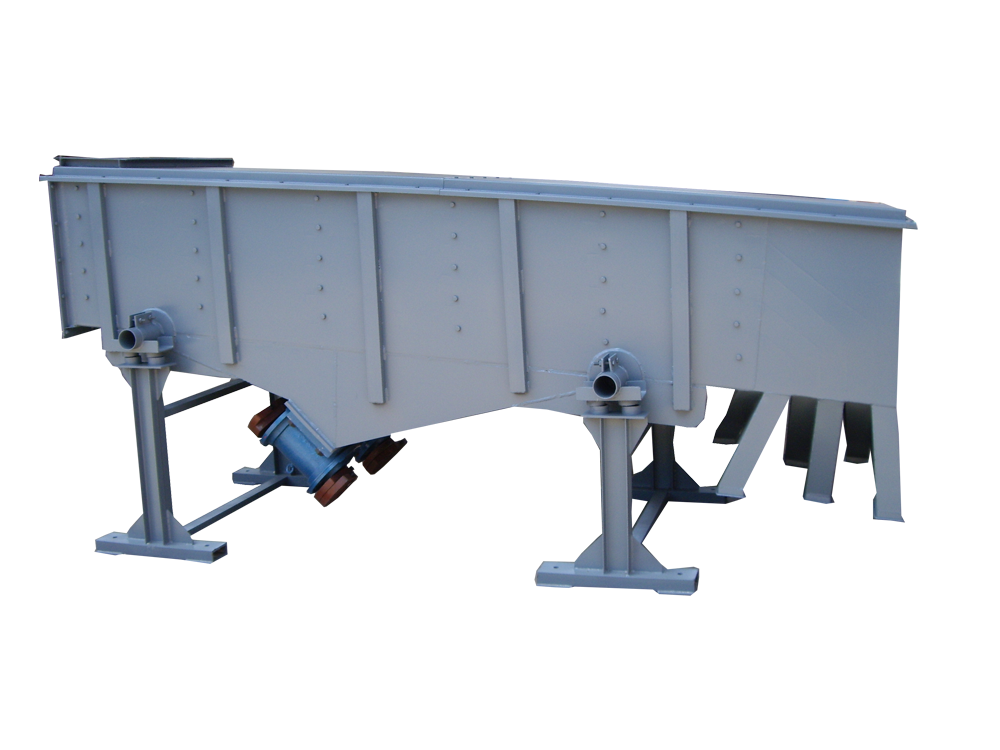

Line vibrating screen is composed of vibrating motor, screen box, screen mesh, vibration transmitting body and vibration damping device. This vibrating screen is suitable for processing granular materials with large output requirements and not too high precision. Linear vibrating screen adopts double vibrating motor drive, when the two vibrating motors do synchronization, anti-percussion rotation, the excitation force produced by its eccentric block in the direction parallel to the motor axis cancel each other, in the direction perpendicular to the motor axis superimposed as a joint force, so the trajectory of the sieve machine is a straight line. Its two motor axis relative to the screen surface has a tilt angle, under the combined force of the excitation force and the self gravity of the material, the material is thrown up on the screen surface jumping forward as a straight line movement, so as to achieve the purpose of screening and grading of materials.

Performance characteristics of linear vibrating screen

Linear vibrating screen utilizes vibrating motor as the vibration source, so that the material is thrown up on the screen net, and at the same time, it makes linear motion forward, and the material enters into the inlet of the screening machine uniformly from the feeder, and then through the multi-layer screen net, it produces several kinds of specifications of the upper part of the screen, the lower part of the screen, and then discharges from the respective outlets respectively. Linear vibrating screen has low energy consumption, high output, simple structure, easy maintenance, fully closed structure, no dust overflow, automatic discharge, more suitable for assembly line operation.

Linear vibrating screen adopts double vibration motor drive, when the two vibration motors do synchronization, anti-percussion rotation, the excitation force produced by its eccentric block in the direction parallel to the motor axis cancel each other, in the direction perpendicular to the motor axis superimposed on a joint force, so the trajectory of the sieve machine is a straight line. The two motor axes have an inclination angle relative to the screen surface, and under the combined effect of the excitation force and the self-gravity of the material, the material is thrown up on the screen surface and jumps forward to make a straight line movement, so as to achieve the purpose of screening and grading of the material.

The specific characteristics of linear vibrating screen are as follows:

1, the use of block eccentric as the excitation force, the excitation force is strong;.

2、Screen beam and screen box are connected by high-strength bolts without welding.

3、Screen machine structure is simple, easy and quick maintenance;.

4、Using tire coupling, flexible coupling, stable operation.

5、High screening efficiency, large handling capacity, long life.

6、High rigidity, high degree of serialization, generalization and standardization, smooth and reliable operation, low noise.

Linear Vibrating Screen Working Principle

When the two vibrating motors installed longitudinally on the screen body do relative operation, the excitation force generated in the transverse direction due to the relative operation of the motors and offset each other, the longitudinal excitation force through the vibration transmitting body transferred to the entire screen box, and make the screen surface vibration, so that the material on the screen surface by its excitation force and jumping on the screen surface in the direction of the material jumping movement, less than the sieve holes of the material through the sieve holes and fall to the lower level, after a continuous jump from the After continuous jumping, the material will flow out from the discharge port. Due to the reasonable screening process, the material can be graded by the vibrating screen, and then several kinds of materials with different particle sizes can be obtained, and the grading operation of the material can be completed.

Linear vibrating screen working characteristics

Linear vibrating screen is the use of inertial exciter to produce vibration, the material is first put into the sieve box, the sieve box is the main working area of the vibrating screen for screening, the vibrator drives the sieve box to vibrate with a specific track, the material in the sieve box in the process of the movement of the screen box to move forward, during this period of time, the sieve mesh will be graded on the material, the diameter of the material than the sieve holes are larger than the material discharged directly from the discharge port.

Screening is carried out in two steps: firstly, fine particles with a size smaller than the screen holes are sent to the screen surface through the layer made up of coarse particles; secondly, the fine particles are passed through the screen mesh. In this way, the screening process is finished.

Linear vibrating screen is used in the assembly line to realize automatic operation, line vibrating screen can also screen powdery and granular materials, which is widely used in chemical, grain, abrasive, fertilizer, carbon and other industries

1、Linear vibrating screen has a high sand rate, low power consumption, power consumption compared with the traditional screening equipment is about 20% lower, will not cause dust pollution, saving energy and the environment.

2、The linear vibrating screen supported by rubber springs is characterized by low noise, low equipment load and no concrete foundation.

3、Linear vibrating screen has the characteristics of small volume, compact structure, occupying less space, simple and convenient production process, convenient repair and maintenance, and saving production investment cost.

4、Linear vibrating screen is composed of stacked screen panels, which has a long service life and can effectively prevent clogging and abrasion.

What is the typical slope of a linear vibrating screen?

The slope of the linear vibrating screen is the angle between the screen surface and the horizontal direction, this slope is related to the screening efficiency, because only the slope is appropriate, for the screening of materials to be more accurate, if the slope is too large, the material on the screen surface stay time will be short, although the discharge is easier, but the material is not carefully screened, if the slope is small, the material stays on the screen surface time often, but the output per unit time will be Low, so the slope of the linear vibrating screen should also be in a reasonable range, so what is the general linear vibrating screen slope?

Linear vibrating screen slope is generally between 0-15°, if you want to screen special materials, you can increase the slope, but not more than 25°. Linear vibrating screen equipment material in the screen surface to do linear movement, general linear screen mesh will have a certain inclination to promote the flow of materials in the screen. The angle between the screen mesh and the horizontal plane is the slope of the linear vibrating screen. The appropriate slope screening effect is better, both the material grading is clear, but also screening efficiency, but in actual production, should be based on the specific nature of the processed materials, as well as the different requirements of the output to adjust the vibrating screen installation slope, but this process should also be in strict accordance with the implementation of the vibrating screen manufacturers.

The inclined slope setting of the linear vibrating screen is related to the materials to be screened. Linear vibrating screen is suitable for screening non-sticky dry powder and particles with a moisture content of less than 7%, and when the moisture content of the material is slightly increased, the linear vibrating screen can adjust the slope appropriately.

The effect of linear vibrating screen slope

1、affect the screening efficiency

The inclined slope of the linear vibrating screen will directly affect the efficiency of the vibrating screen. If the slope is too large, then the material on the screen surface residence time is short, easy to discharge, but it will cause the material screening is not uniform, affecting the screening fineness.

2、 affect the screening yield

Linear vibrating screen equipment material in the screen surface to do linear movement, general linear screen screen will have a certain inclination to promote the flow of materials in the screen. In general, if the customer does not require screening fineness, if there are requirements for screening yield, we can appropriately adjust the slope of the linear vibrating screen to enhance the jumping speed of the material on the screen surface, and promote the rate of material over the net.

3、 affect the material classification

The inclined slope of linear vibrating screen will affect the grading of materials. The screening principle of linear vibrating screen is that the material is forced forward to do jumping movement, and the material falls upward by the force of the sieve drive parabolic movement. Slope is too small, the material jump height is low, the force of falling screen becomes small, the grading of the material is not sufficient, the appropriate slope will make the material grading clear.

About linear vibrating screen installation and commissioning and test run

Installation:

1, when the machine is installed, the equipment should be installed in strict accordance with the installation diagram, and the foundation should have sufficient rigidity and strength to support the dynamic and static loads of the vibrating screen.

2、Motor can be installed horizontally. The motor should be fastened on the mounting surface, and the mounting surface must be smooth and level.

3、When installing, the corners of the screen box should be horizontal.

4、Ensure that a clearance of 75mm should be maintained between the screen box and non-moving parts such as hopper and chute.

5、Adjustment of vibration force.

6, the motor should be reliable grounding, the motor has a grounding device, the lead end has a sign, can also use the foot solid bolt grounding.

7, the motor leads using four-core rubber cable YZ-500V, connecting the power supply when the lead cable does not allow sharp folding, and vibration with a reliable fixed body.

Adjustment and test run:

1, the spring must be in a vertical state, the spring upper support and the spring contact surface must become horizontal, after adjustment, bolt the spring upper support on the trunnion of the screen box, and then welded into one.

2、No-load test run time is not less than 2 hours, no-load test run qualified, can be put into the load test run, load test can be carried out according to the requirements of the process test run.