Banana style screens are an important tool in the screening industry, used to separate materials of different sizes and shapes. Unlike traditional linear motion screens, banana style screens have a more curved surface which enables better handling of large volumes of material and improves screening efficiency. This unique design reduces pegging and blinding, two common issues that can occur during the screening process.

In this article, we will explore how banana style screens work and how they can improve screening efficiency. We will also discuss the advantages of using banana style screens compared to traditional linear motion screens, as well as some common applications for these types of screens.

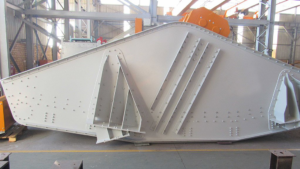

Understanding Banana Style Screens

Banana style screens, also known as curved or multi-slope screens, have become increasingly popular in the screening industry due to their superior performance and efficiency. These types of screens are mainly used for heavy-duty applications such as mining, mineral processing, and aggregates.

The biggest difference between banana style screens and traditional linear motion screens is the shape of the screen surface. Traditional linear motion screens have a flat surface, while banana style screens have a curved surface with multiple slopes. This unique design allows the material to move at different speeds and angles along the screen, resulting in better separation and reduced pegging or blinding.

One of the main advantages of banana style screens is their ability to handle high volumes of material. Due to the curved surface, these screens have a larger effective screening area compared to linear motion screens. This means that more material can be screened at once, resulting in higher productivity and efficiency.

Furthermore, the curved surface of banana style screens also allows for better dewatering of wet materials. The material is able to move along the screen at different speeds, allowing water to drain off easily. This is especially beneficial for applications where dewatering is essential, such as in the production of sand and gravel.

Another key feature of banana style screens is their ability to reduce the chances of pegging and blinding. Pegging occurs when particles become lodged in the screen openings, while blinding happens when fine material fills up the openings on the screen surface. These issues can greatly affect screening efficiency and result in downtime for cleaning and maintenance.

Why Choose Banana Style Screens?

With their unique design and superior performance, it’s no wonder that banana style screens are becoming the preferred choice for many industries. Compared to traditional linear motion screens, banana style screens offer several advantages that can greatly improve screening efficiency.

One of the main benefits is the reduced chance of pegging and blinding, as mentioned earlier. This allows for a more continuous and efficient screening process, resulting in higher productivity and lower downtime.

Banana style screens also have a longer lifespan compared to linear motion screens. The curved surface helps distribute the stress evenly, reducing wear and tear on individual screen panels. This means less frequent replacements are needed, saving time and costs for maintenance.

Moreover, banana style screens have a lower bed depth, which means that the material doesn’t have to travel as far to be screened. This reduces the chance of material getting stuck or slowing down the screening process.

In addition to these advantages, banana style screens also offer a more accurate and precise separation of materials due to their multi-slope design. This makes them suitable for applications where specific particle sizes need to be achieved, such as in the production of fine aggregates for construction materials.

How Does A Banana Style Screen Improve Screening Efficiency?

Banana style screens improve screening efficiency in several ways. Their unique design allows for a larger effective screening area, which means more material can be screened at once. This results in higher productivity and less time wasted on multiple passes.

The curved surface of banana style screens also enables better handling of large volumes of material. The material is able to move at different speeds and angles, reducing the chance of blockages or buildup on the screen surface. This leads to a more continuous screening process and reduces the need for frequent cleanings.

Furthermore, with their ability to dewater wet materials efficiently, banana style screens can improve screening efficiency in industries where this is essential, such as in sand and gravel production. The material is able to move along the screen at different speeds, allowing water to drain off easily and resulting in a drier end product.

Banana style screens also have a higher throughput compared to linear motion screens. This means they are able to handle larger volumes of material in a shorter amount of time, making them ideal for heavy-duty applications where efficiency is crucial.

The reduced chance of pegging and blinding also greatly contributes to improved screening efficiency. These issues can significantly slow down the screening process and require frequent interruptions for cleaning and maintenance. With banana style screens, this is less of a concern, allowing for a more continuous and efficient operation.

Should You Consider A Banana Style Screen?

Ultimately, the decision to choose a banana style screen over a traditional linear motion screen depends on the specific needs and requirements of your industry or application. However, with their numerous advantages and superior performance, it’s definitely worth considering a banana style screen for improved screening efficiency.

If you are dealing with high volumes of material and require a continuous and efficient screening process, banana style screens are an excellent choice. Their ability to handle wet materials and reduce the chances of pegging and blinding make them suitable for a variety of industries, including mining, mineral processing, and aggregates.

Moreover, with their longer lifespan and lower maintenance requirements, banana style screens can also help save time and costs in the long run. This is especially beneficial for industries where downtime can result in significant losses.

It’s also worth noting that banana style screens are available in a variety of sizes and configurations to cater to different material types and screening requirements. This flexibility makes them suitable for a wide range of applications and industries.

How much maintenance do Banana Style Screens require?

One of the main advantages of banana style screens is their lower maintenance requirements compared to traditional linear motion screens. This is due to their unique design and ability to handle wet materials efficiently, reducing the chances of pegging and blinding.

However, like any equipment, banana style screens still require some maintenance to ensure optimal performance and longevity. The frequency and extent of maintenance will depend on factors such as the volume and type of material being screened, as well as the operating conditions.

Regular inspection of the screen panels is necessary to identify any wear or damage that may affect screening efficiency. This can include checking for cracks, tears, or holes in the screen surface, as well as monitoring the tension of the screen panels and ensuring they are securely fastened.

In addition, keeping the screen surface clean is crucial for preventing buildup and blockages that can hinder screening efficiency. This may involve regular washing with water or using specialized cleaning solutions to remove stubborn materials.

Depending on the material being screened, it may also be necessary to replace worn or damaged screen panels periodically. This will help maintain the effectiveness of the screen and prevent any major issues that may impact productivity.

Difference between Banana Style Screens and Traditional Linear Motion Screens

The main difference between banana style screens and traditional linear motion screens lies in their design. Banana style screens have a curved surface with multiple slopes, while traditional linear motion screens have a straight, single slope surface.

This unique design of banana style screens allows for more effective handling of large volumes of material, resulting in improved screening efficiency. The curved surface also reduces the chance of blockages and buildup, leading to a more continuous and efficient screening process.

In contrast, traditional linear motion screens are more prone to pegging and blinding due to their single slope design. This can significantly slow down the screening process and require frequent interruptions for cleaning and maintenance.

Another key difference is in the screening area. Banana style screens have a larger effective screening area, allowing for more material to be screened at once. This leads to higher productivity and less time wasted on multiple passes, making them ideal for heavy-duty applications.

On the other hand, traditional linear motion screens have a smaller screening area and may require multiple passes to achieve the desired level of separation. This can limit their efficiency and make them more suitable for smaller scale operations.

In terms of maintenance, banana style screens require less frequent cleaning and have lower wear and tear compared to traditional linear motion screens. This is due to their ability to handle wet materials efficiently and reduce the chances of blinding and pegging.

Should You Make the Switch to Banana Style Screens?

Making the switch to banana style screens can have numerous benefits for your screening process, including improved efficiency and reduced maintenance. However, it’s important to consider your specific industry or application needs before making a decision.

If you are dealing with high volumes of material and require continuous and efficient screening, then banana style screens are definitely worth considering. Their ability to handle wet materials and reduce the chances of pegging and blinding make them a popular choice in industries such as mining, mineral processing, and aggregates.

Moreover, their longer lifespan and lower maintenance requirements can help save time and costs in the long run. This is advantageous for industries where downtime can result in significant losses.

However, if your screening process involves smaller volumes of material or requires a more precise separation, then traditional linear motion screens may be a better fit. It’s important to assess your specific needs and consider factors such as material type, operating conditions, and required level of efficiency before making the switch.

Another important consideration is the initial investment cost. While banana style screens may have higher upfront costs compared to traditional linear motion screens, their long-term benefits can outweigh the initial expense.

Tips for Maintaining Banana Style Screens

To ensure optimal performance and longevity of your banana style screens, it’s important to follow a few tips for maintenance. Regular inspection and cleaning are key to preventing issues that may impact screening efficiency.

Firstly, make sure to regularly inspect the screen panels for any wear or damage. This can include cracks, tears, or holes in the surface, as well as loose or damaged fasteners. Any issues should be addressed immediately to avoid further damage and maintain the effectiveness of the screen.

In addition, keeping the screen surface clean is crucial for preventing buildup and blockages. This can be achieved through regular washing with water or using specialized cleaning solutions for stubborn materials.

Furthermore, it’s important to monitor the tension of the screen panels to ensure they are securely fastened. This can be done with a tension gauge and any loose panels should be tightened accordingly.

Depending on the material being screened, it may also be necessary to replace worn or damaged screen panels periodically. This will help maintain the efficiency of the screen and prevent any major issues that may impact productivity.

Lastly, following proper installation and operating procedures can also help prolong the lifespan of your banana style screens. This includes ensuring proper alignment and tensioning of the screen panels, as well as adjusting settings to fit your specific material and application needs. Regular maintenance checks should also be scheduled to catch any potential issues before they become major problems.

FAQs

Does the curved surface of banana style screens affect their durability?

The curved surface of banana style screens does not affect their durability. In fact, it can increase their lifespan by reducing wear and tear on the screen panels.

Are banana style screens suitable for all types of materials?

Banana style screens are most effective for handling wet and sticky materials. They may not be ideal for dry, fine materials that require a more precise separation.

How often should banana style screens be inspected and cleaned?

Banana style screens should be inspected and cleaned regularly, with the frequency depending on the specific material being screened. In general, it is recommended to inspect and clean them at least once a week to maintain optimal performance. However, in industries where the screens are subjected to heavy wear and tear, more frequent inspections may be necessary.

Are banana style screens more expensive than traditional linear motion screens?

Banana style screens may have a higher upfront cost compared to traditional linear motion screens. However, their longer lifespan and lower maintenance requirements can make them a more cost-effective option in the long run. Additionally, their higher efficiency and productivity can also lead to overall cost savings for industries that require continuous and efficient screening processes.

Conclusion

Banana style screens offer numerous advantages over traditional linear motion screens, such as improved efficiency and reduced maintenance. While they may not be suitable for all types of materials or applications, they are definitely worth considering for industries dealing with high volumes of wet and sticky materials. Proper maintenance and regular inspections are key to ensuring optimal performance and longevity of these screens.

By carefully assessing your specific needs and considering factors such as initial investment cost, material type, and required level of efficiency, you can determine if making the switch to banana style screens is the right decision for your screening process. With proper care and maintenance, these screens can greatly improve productivity and save time and costs in the long run.